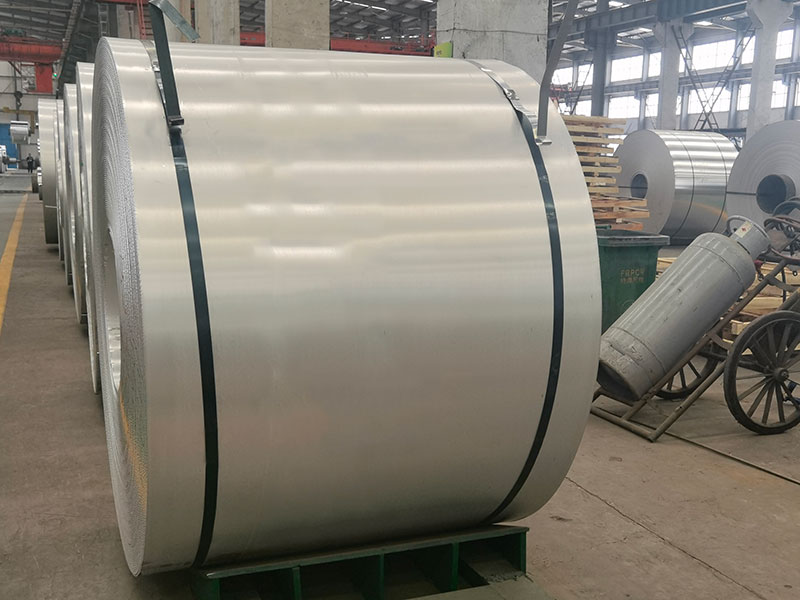

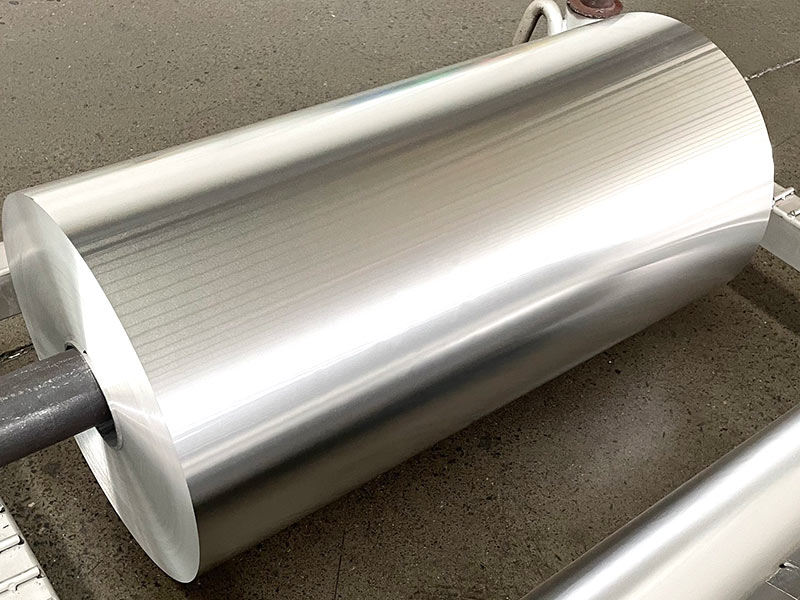

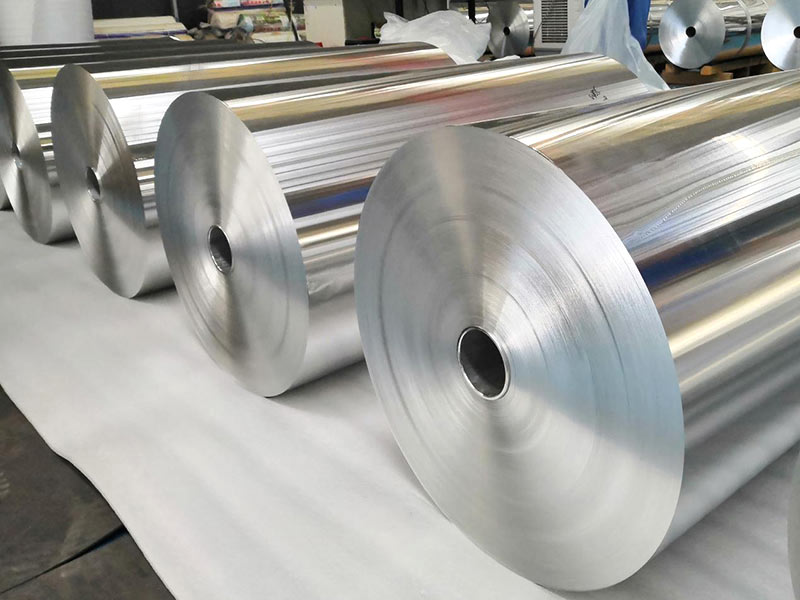

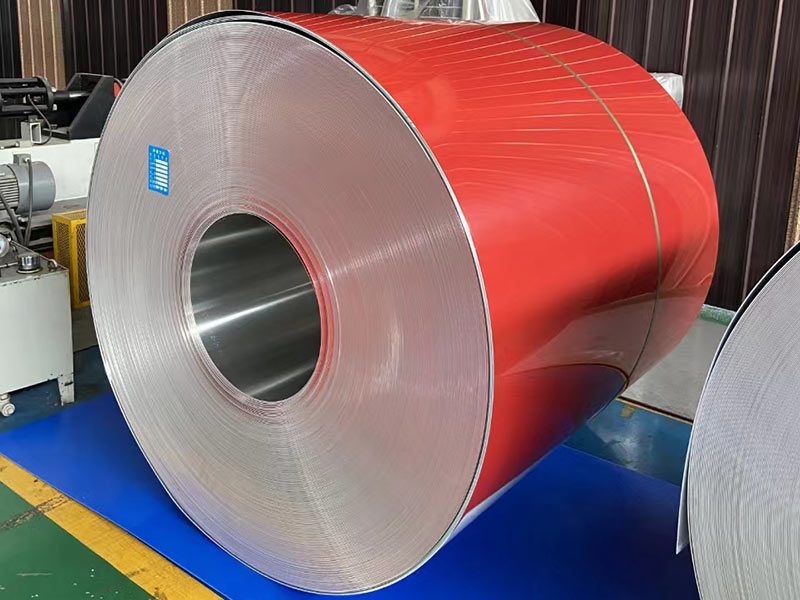

Hot Rolled Aluminum Coil

Hot-rolled aluminum coil is a process in which aluminum alloy materials are heated to high temperatures and then formed on a hot rolling mill. The ...

Email: export@xienuoenterprise.com

Hot Rolled Aluminum Coil

Hot-rolled aluminum coil is a process in which aluminum alloy materials are heated to high temperatures and then formed on a hot rolling mill. The hot-rolled aluminum coil process involves multiple steps, including pretreatment, hot rolling, cold rolling, quenching and surface treatment.

Chemical Composition Of Commonly Used Alloys For Hot-rolled Aluminum Coils

| Alloy | The Chemical Composition (%) Of Wanda’s typical product | ||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al | |

| 5005 | 0.126 | 0.376 | 0.010 | 0.003 | 0.95 | 0.010 | 0.017 | 0.018 | Remain |

| 5052 | 0.088 | 0.244 | 0.006 | 0.065 | 2.33 | 0.175 | 0.013 | 0.016 | Remain |

| 5754 | 0.080 | 0.292 | 0.025 | 0.207 | 2.85 | 0.071 | 0.007 | 0.021 | Remain |

| 6061 | 0.606 | 0.321 | 0.256 | 0.063 | 0.968 | 0.171 | 0.011 | 0.022 | Remain |

Advantages Of Hot Rolled Aluminum Coil

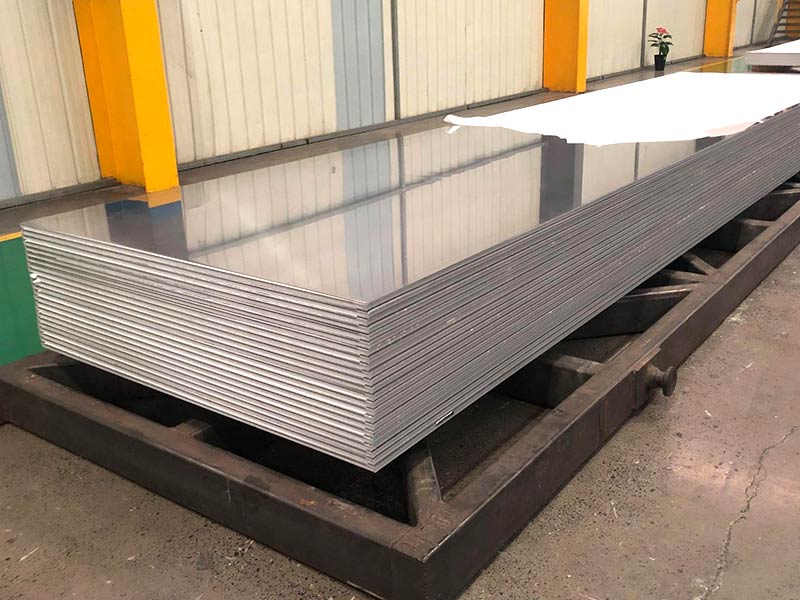

The advantages of hot-rolled aluminum coils include high production efficiency, low energy consumption, good mechanical properties and surface quality. Compared with cold-rolled coils, hot-rolled coils have higher plastic deformation capabilities and can roll products of larger sizes and complex shapes. Hot-rolled coils also have good corrosion resistance and welding properties, making them suitable for various engineering applications.

During hot rolling, the metal has high plasticity and low deformation resistance, which greatly reduces the energy consumption of metal deformation. Hot rolling can improve the processing performance of metals and alloys, that is, break the coarse grains in the casting state, significantly heal cracks, reduce or eliminate casting defects, transform the as-cast structure into a deformed structure, and improve the processing performance of the alloy.

Hot-rolled aluminum plates have better deep drawing and bending properties, so they are suitable for deep processing.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!