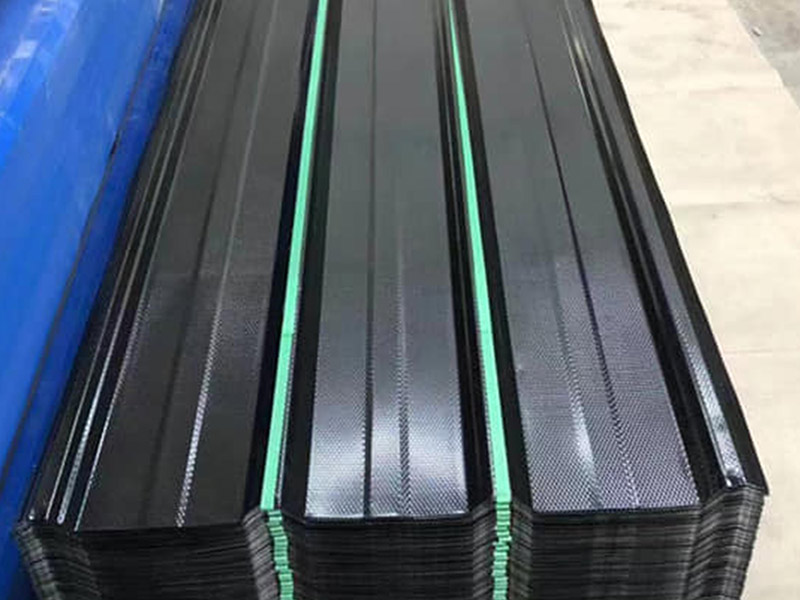

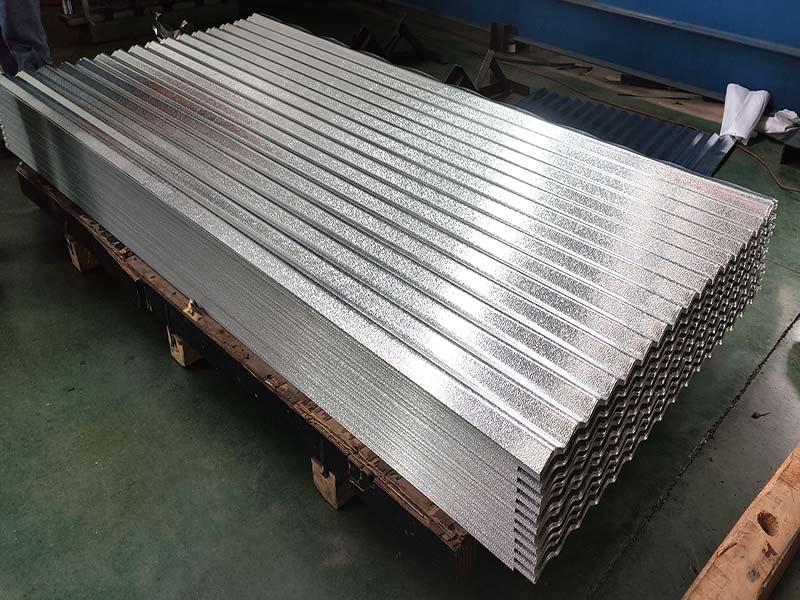

Color Coated Aluminum Roofing Sheet

Color-coated aluminum roofing sheet are suitable for a variety of building types, including residential, commercial, industrial and more. It is durable and does not require any maintenance costs during normal use. It has extremely high recycling value and saves costs. It is suitable for roofing and renovation.

Email: export@xienuoenterprise.com

Color Coated Aluminum Roofing Sheet

Color-coated aluminum roofing sheet come in a variety of colors and are commonly used in large landmark buildings such as some sports venues, convention and exhibition centers, airports, stations, and large industrial plants.

Color Coated Aluminum Roofing Sheet Common Alloys And States

| Series | Alloy | Temper |

| 1000 series | 1050 1060 1100 1200 | O H12 H22 H14 H24 H16 H26 H18 |

| 2000 series | 2A12 | H112 T4 |

| 3000 series | 3003 3A21 | O H12 H22 H14 H24 H16 H26 H18 |

| 3004 3105 | O-H18 H32 H34 H111 H112 | |

| 5000 series | 5052 5005 5754 5083 | O H32 H34 H111 H112 |

| 6000 series | 6061 6082 | T6 T4 |

| 7000 series | 7075 | T651 |

| 8000 series | 8011 | O H22 H18 |

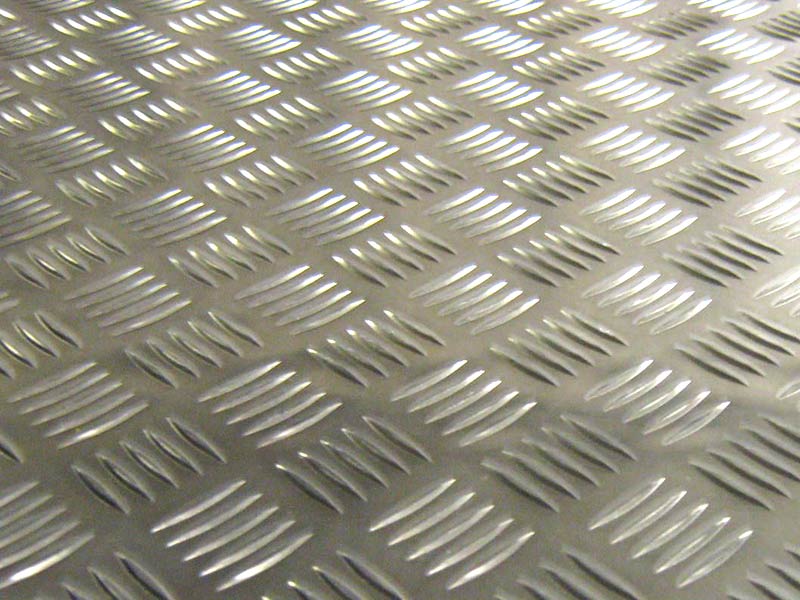

Specifications Of Color Coated Aluminum Roofing Sheet

| ALLOY: | AA1100, 3003, 3004, 3105, 5006, 5052, 6061,7075,8011 |

| THICKNESS: | 0.08-4.0mm |

| WIDTH: | <1800mm |

| COILS CORE DIAMETER: | 150mm ,405mm, 505mm, 508mm, 510mm |

| COATING THICKNESS: | PVDF >=25micron POLYESTER>=18micron |

| COLOR STANDARD: | E < 2 or it is not obvious by eyeballing |

| PENCIL HARDNESS: | > 2HB |

| COATING ADHESIVE: | not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

| BEND STENGTH: | >100 times |

| BOILING POINT: | no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

| CORROSIVE: | surface deep in the 5% muriatic acid and 5% NaCL, interior deep in the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

| PACKING | standard export package (waterproof kraft paper+galvanized steel sheet) |

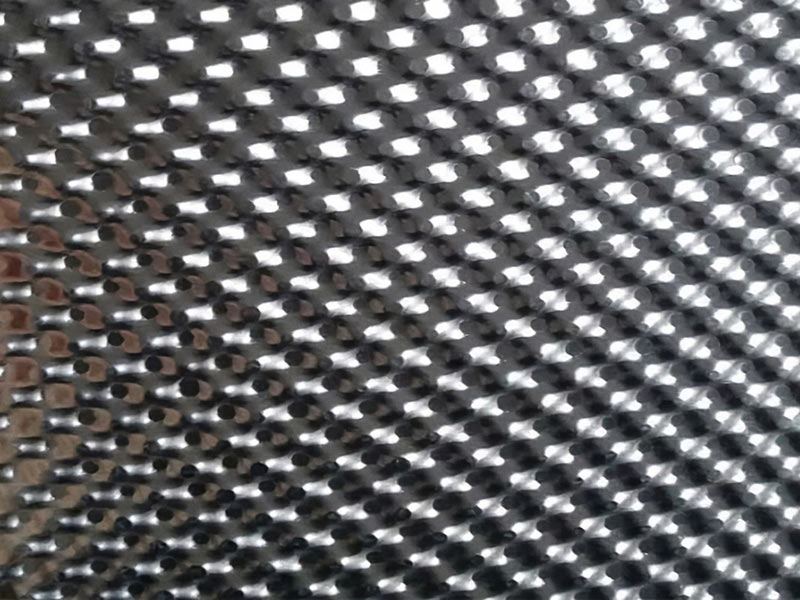

Color Coated Aluminum Roofing Sheet Features

1. Made of high-strength and corrosion-resistant aluminum alloy; the anti-corrosion capability has a service life of not less than 40 years in ordinary environments;

2. The surface fluorocarbon coating increases the resistance to acid rain and industrial corrosion, and at the same time does not react to ultraviolet rays, resists microorganisms, and does not age;

3. Has good thermal radiation resistance;

4. It is durable and does not require any maintenance costs during normal use. It has extremely high recycling value and saves costs. It is suitable for roofing and renovation;

5. Can be adapted to various roof shapes - spherical, fan-shaped, arc-shaped, to meet the designer's design concepts to the greatest extent;

6. Light weight, the density of aluminum is 2.73g/m3, only 1/3 of steel.

Applications Of Color Coated Aluminum Sheet:

Color-coated aluminum roofing sheet are suitable for a variety of building types, including residential, commercial, industrial and more.

| Building | Venetian blinds, rolling shutters, ceiling panels, roofing, façade, ACP Panel. Eveas etc. |

| Roller Shutter | Aluminium Composite Panel (ACP), Ceiling, Roofing etc |

| Industry | An ideal material for white appliances such as refrigerator due to it’s property of electrical and thermal conductivity, and corrosion resistance |

| Transport | truck body, caravan, buses, insulated and refrigerated vehicle |

| Signs | Application in Signs requires high colour consistency and flat surface. UAL can fulfill the requirements with excellent performance. |

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!