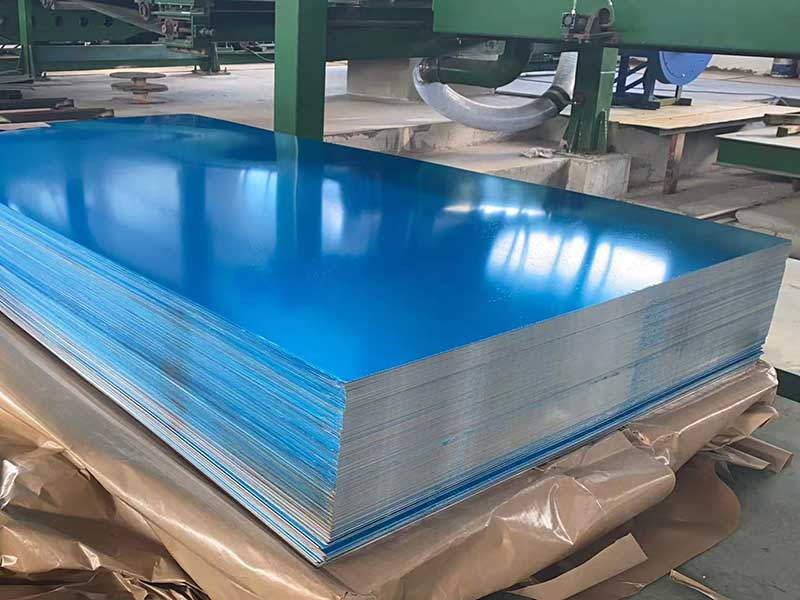

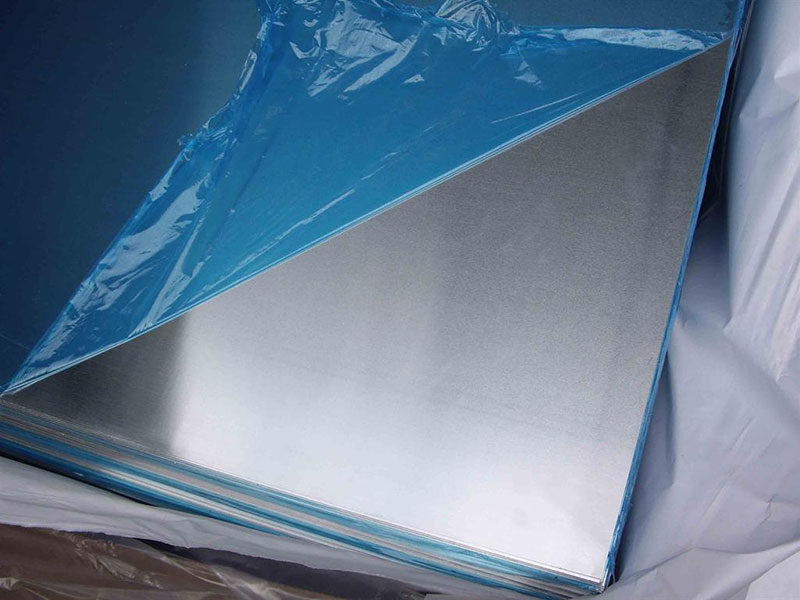

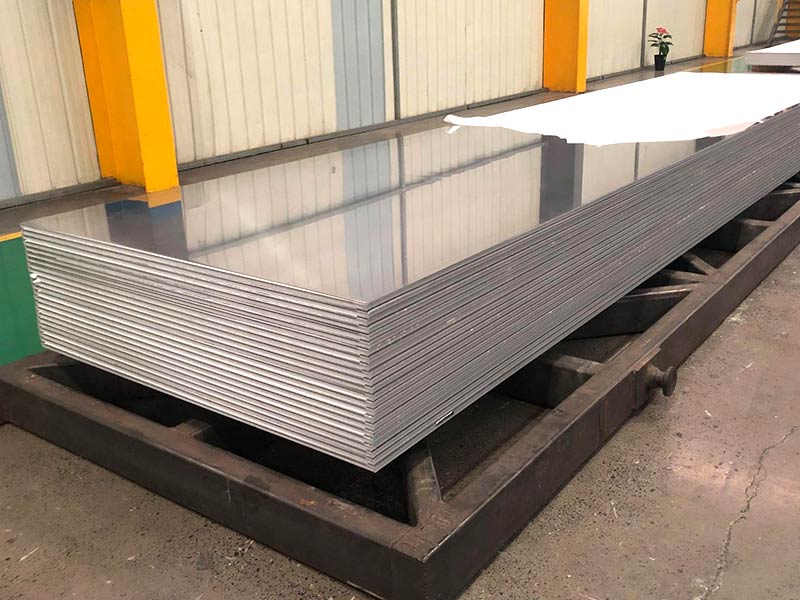

6000 Series Aluminum Sheet and Plate

Good strength and toughness: After heat treatment in the T6 state, the six series aluminum alloy has high mechanical properties such as ultimate tensile strength, yield strength and elongation at break.

Email: export@xienuoenterprise.com

6000 Series Aluminum Sheet and Plate

The 6000 series mainly contains magnesium and silicon, so it concentrates the advantages of the 4000 series and 5000 series. 6061 is a cold-treated aluminum forging product, suitable for applications with high requirements for corrosion resistance and oxidation resistance. It has good workability, easy coating, and good processability. The 6000 series aluminum alloy represents 6061.

6000 Series Aluminum Plate DC / CC Alloy Designation (For Reference)

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 6xxx Series | 6061 | 6061 | ENAW-6061 |

| 6082 | 6082 | ENAW-6082 |

6000 Series Aluminum Plate DC / CC Chemical Compositing

Chemical Composition conforms to Chinese, American and European standard specification (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti | Others:Each |

| 6061 | 0.4-0.8 | 0.7 | 0.15-0.40 | 0.15 | 0.8-1.2 | 0.25 | 0.04-0.35 | 0.15 | 0.05 |

| 6082 | 0.7-1.3 | 0.5 | 0.10 | 0.4-1.0 | 0.6-1.2 | 0.20 | 0.25 | 0.10 | 0.05 |

Mechanical Properties Of 6000 Series Aluminum Plate DC / CC

| Yield Strength | »90-360Mpa |

| Tensile Strength | »150-395Mpa |

| Hardness | 42-120HB |

Product Videos

6000 Series Aluminum Plate DC / CC Available Size Range

| Alloy | 6000 Series Aluminum Plate |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, T4, T6, T651. |

| Thickness(mm) | 0.2-100mm |

| Width(mm) | 500-2800mm |

| Standards | GB, EN, ASTM, AISI, JIS, DIN. |

| Surface Treatment | Anodizing, Color coating, Embossing, Lamination, Polishing etc. |

| Packaging | Standard export wooden box/pallet packaging, suitable for sea transportation |

6000 Series Aluminum Plate CC / DC Temper (For Reference)

| Temper | Definition |

| O | Annealed state. This state applies to the alloys that are fully annealed to obtain the lowest strength. |

| T4 | Solution heat-treated and naturally aged |

| T5 | Solution heat-treated, stress relived by stretching and naturally aged |

| T6 | Solution heat-treated and then artificially aged |

| T651 | Heat treatment temper. Solution heat-treated, stress relived by stretching and artificially aged |

Characteristics Of 6000 Series Aluminum Plate DC / CC

1. Good strength and toughness: After heat treatment in the T6 state, the six series aluminum alloy has high mechanical properties such as ultimate tensile strength, yield strength and elongation at break.

2. Good corrosion resistance: Six series aluminum alloy has good corrosion resistance, especially in harsh environments such as sea water, it can still maintain good surface finish and corrosion resistance.

3. Easy to process and weld: Six series aluminum alloy has good processing performance and weldability, and can be formed and processed using various processing methods.

Application Of 6000 Series Aluminum Plate DC / CC

1. Aviation field: Six series aluminum alloy is one of the main materials widely used in the aviation industry. Because it has the advantages of light weight, high strength, corrosion resistance, and wear resistance, it can be used to manufacture aircraft shells, wings and other components.

2. Aerospace field: Six series aluminum alloy is also one of the main materials widely used in the aerospace industry. For example, it can be used to manufacture rocket propellers, spacecraft casings, etc.

3. Automobile field: Six-series aluminum alloys can be used in car bodies, engine blocks and other components in automobile manufacturing, which can reduce car quality, improve fuel efficiency, and reduce environmental pollution.

4. Construction field: Six-series aluminum alloys can be used in doors, windows, curtain walls, elevator shafts, subway tunnels and other components in buildings. They have the advantages of light weight, corrosion resistance, and good decorative properties.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!