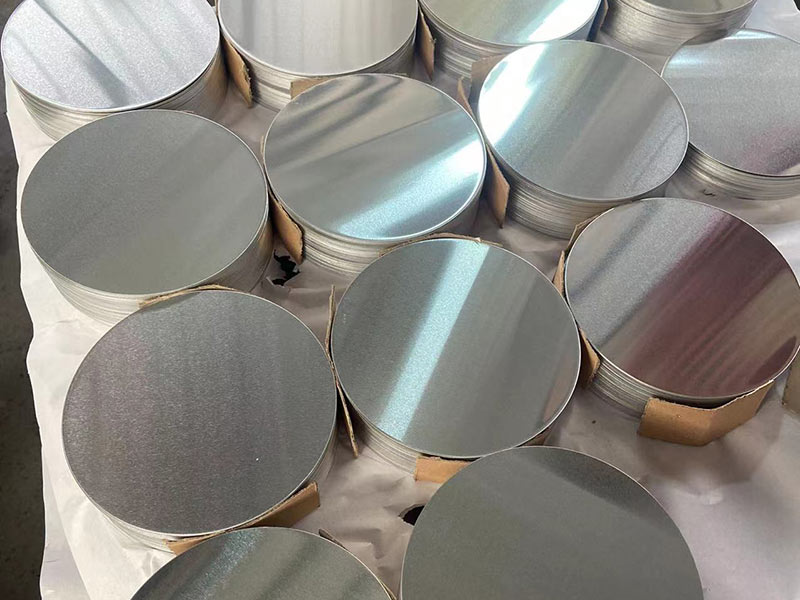

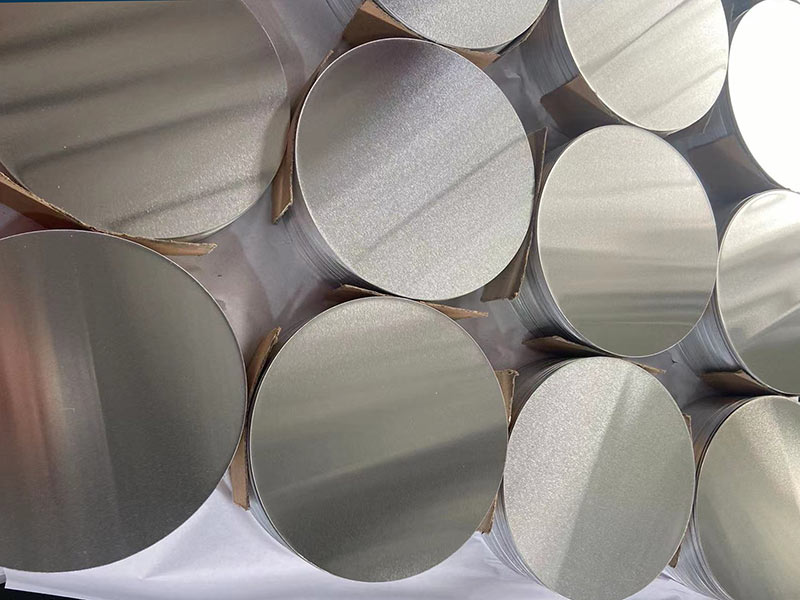

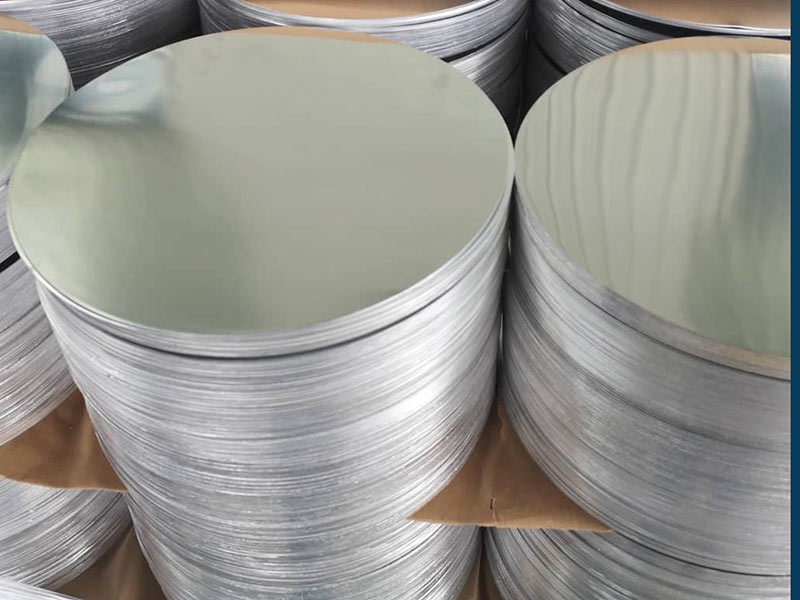

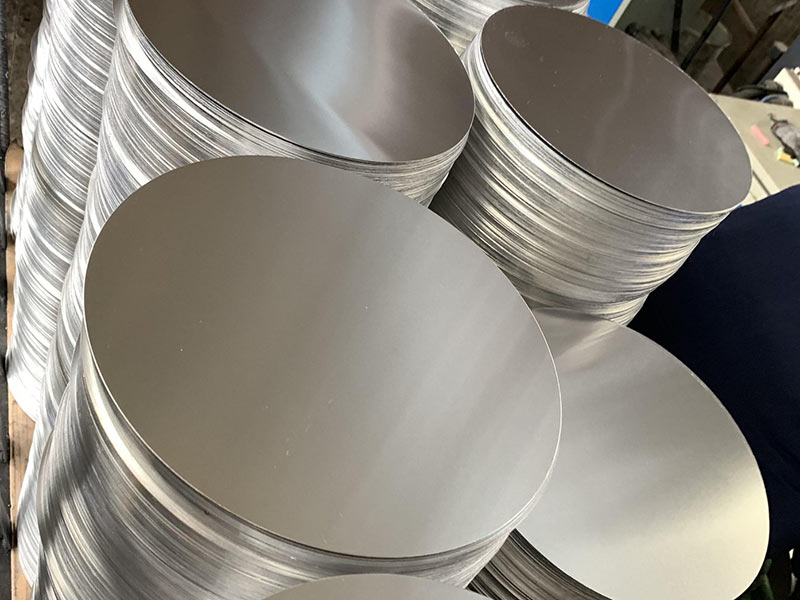

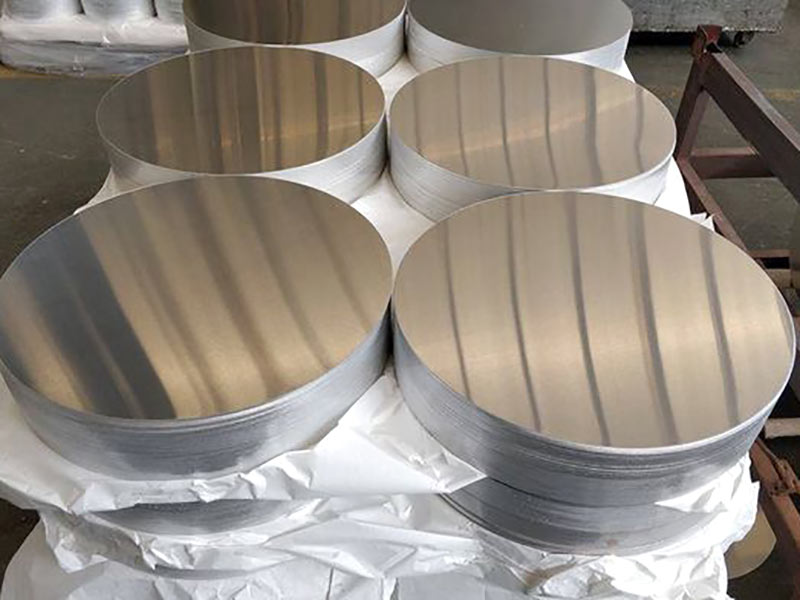

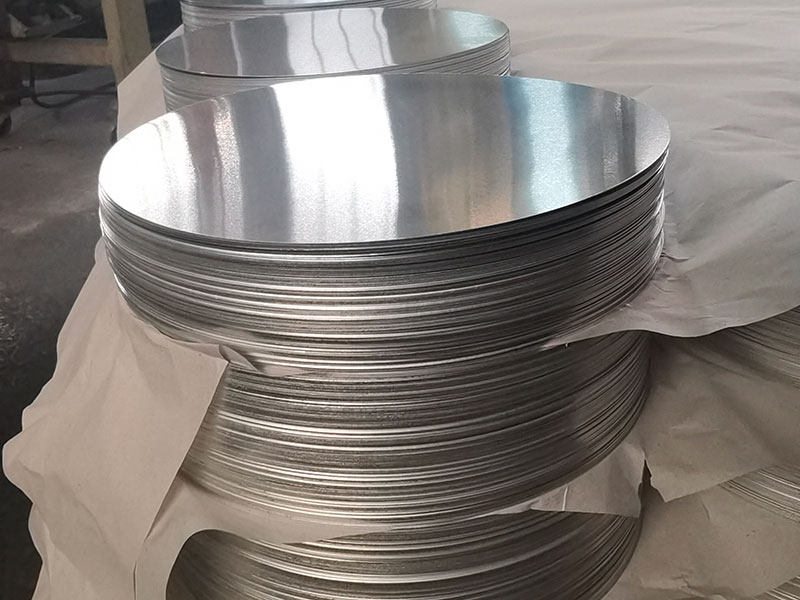

5052 Aluminum Circle and Disc

The 5000 series is an aluminum-magnesium alloy series, such as 5052, etc. The content of the main element magnesium is between 3-5%, which can be called aluminum-magnesium alloy. 5052 aluminum discs are preliminary processed products after continuous stamping of aluminum coils.

Email: export@xienuoenterprise.com

5052 Aluminum Circle and Disc

The 5000 series is an aluminum-magnesium alloy series, such as 5052, etc. The content of the main element magnesium is between 3-5%, which can be called aluminum-magnesium alloy. 5052 aluminum discs are preliminary processed products after continuous stamping of aluminum coils.

5052 Aluminum Circle DC / CC Alloy Designation (For Reference)

5052 aluminum circles blank of XieNuo Aluminum Company is produced according to the standards of chinese GB.

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 5xxx Series | 5052 | 5052 | – |

5052 Aluminum Circle DC / CC Chemical Compositing

Chemical Composition conforms to Chinese, American and European standard specification (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Others:Each |

| 5052 | 0.25 | 0.40 | 0.10 | 0.10 | 2.2-2.8 | 0.15-0.35 | 0.10 | 0.05 |

Product Videos

Mechanical Properties Of 5052 Aluminum Circle

| Tensile strength σb (MPa) | 173-244 |

| Conditional yield strength σ0.2 (MPa) | ≥70 |

5052 Aluminum Circle CC / DC Diameter Tolerance

| Nominal Diameter | Tolerance |

| Diameter tolerance | +/- 1mm |

5052 Aluminum Circle CC / DC Temper (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

Characteristics Of 5052 Aluminum Circle

The main features of 5052 aluminum discs are low density, high tensile strength and high elongation. The weight of aluminum-magnesium alloy is lower than other series under the same area, and it is widely used in conventional industries.

The most commonly used 5052 is the most representative alloy with medium strength. It has good corrosion resistance, weldability and formability, especially high fatigue strength and good seawater corrosion resistance. It is often used to meet strength requirements. High product.

Application Of 5052 Aluminum Circle

5052 aluminum wafers are mainly used in lamps, kitchenware, electronic and electrical casings, etc. The state is basically selected as 0 state, which requires good extension performance.

Aluminum discs for stamping and drawing of cookware, lamps, etc.: have the advantages of high surface finish, no scratches, and high elongation. In recent years, the market share has been increasing.

At present, the company's aluminum wafers are mainly hot-rolled substrates with good grain size control and are suitable for deep drawing and drawing. Aluminum wafers of various diameters can be provided according to user requirements.

Aluminum discs for traffic signs: This type of aluminum discs is a bent disc. It is an aluminum plate processed by rounding and bending equipment. It is suitable for use in various types of traffic signs, traffic signs and other industries. It can be customized and processed according to the diameter. Welcome to consult .

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!