5005 Aluminum Coil and Strip

The performance of 5005 aluminum is reflected in its good weldability, processability, formability and excellent anodizing effect. 5005 aluminum alloy is an aluminum alloy material with lower density and has a wide range of applications.

Email: export@xienuoenterprise.com

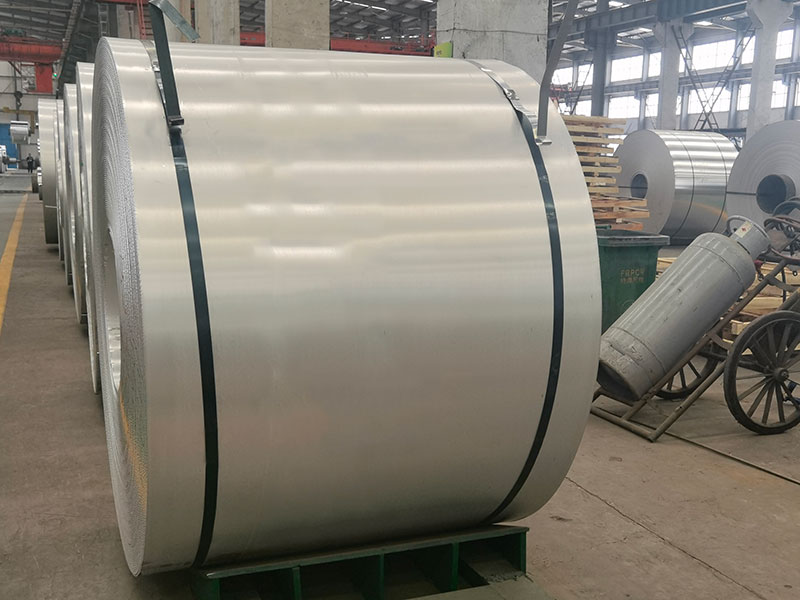

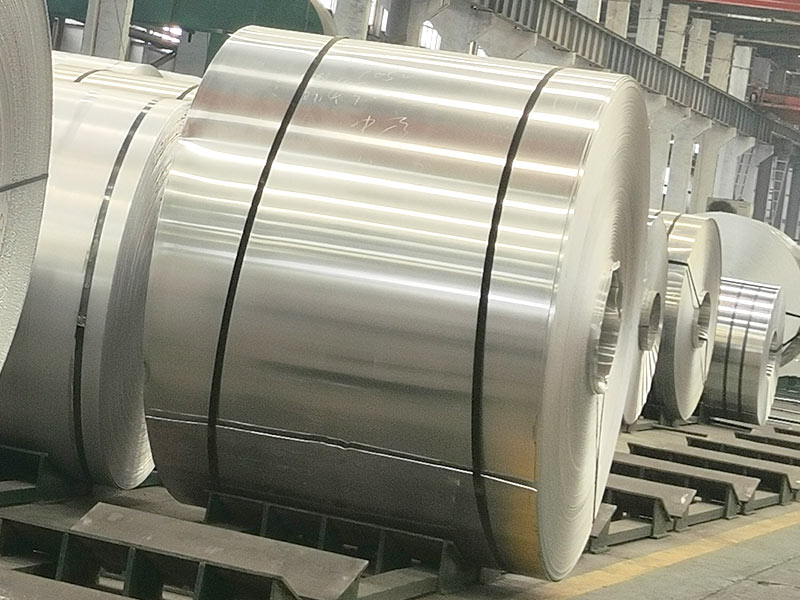

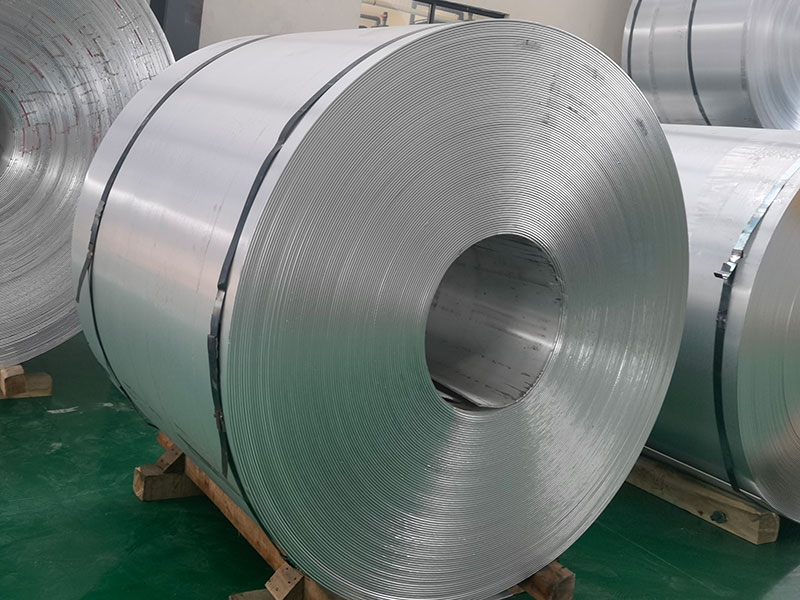

5005 Aluminum Coil and Strip

5005 aluminum coil refers to cast and rolled 5005 aluminum coil, which is drawn and bent to form a coil, and then processed by flying shear.

5005 Aluminum Coil DC / CC Alloy designation (For Reference)

Comparison of Alloy Designations for 5005 aluminum sheet coil.

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 5xxx Series | 5005 | 5005 | EN AW-5005 |

5005 Aluminum Coil DC / CC Chemical Compositing

Chemical Composition conforms to Chinese, American and European standard specification (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Cr | Others:Each |

| 5005 | 0.30 | 0.7 | 0.2 | 0.2 | 0.5-1.1 | 0.25 | 0.1 | 0.05 |

Product Videos

Mechanical properties of 5005 aluminum coil

| Tensile strength σb (MPa) | 100~205 |

| Elongation δ10 (%) | 1~8 |

| Annealing temperature is | 345℃ |

5005 Aluminum Coil DC / CC Temper designation (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

5005 Aluminum Coil DC / CC Available Size Range

| Alloy | 5005 |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, T4, T6, T651. |

| Thickness(mm) | 0.3-6.0mm |

| Width(mm) | 30-1850mm |

| Standards | GB, EN, ASTM, AISI, JIS, DIN. |

| Surface Treatment | Anodizing, Color coating, Embossing, Lamination, Polishing etc. |

| Packaging | Standard export wooden box/pallet packaging, suitable for sea transportation |

Characteristics of 5005 aluminum coil

The performance of 5005 aluminum is reflected in its good weldability, processability, formability and excellent anodizing effect.

5005 aluminum alloy is an aluminum alloy material with lower density and has a wide range of applications. Its lightweight properties make it widely used in aerospace, automotive manufacturing, construction and electronics. By utilizing the excellent properties of 5005 aluminum alloy, lightweight design of the material can be achieved and product performance and efficiency can be improved.

Application of 5005 aluminum coil

5005 aluminum alloy is often used in the aerospace field to manufacture aircraft, spacecraft and satellites. Its low density can reduce the weight of the entire structure and improve flight efficiency and fuel utilization.

5005 aluminum alloy is also commonly used in the automobile manufacturing industry. The use of 5005 aluminum alloy can reduce the overall weight of the automobile, improve fuel economy, and has good strength and corrosion resistance, extending the service life of automobile parts.

5005 aluminum alloy is also widely used in construction, electronics, household products and other fields.

In the construction field, 5005 aluminum alloy is often used to manufacture doors, windows, curtain walls, roofs and other structures. Its lightweight properties can reduce the load of the building and improve the stability of the overall structure.

In the electronics field, 5005 aluminum alloy is often used to manufacture components such as electronic housings and radiators. It has excellent thermal conductivity and can effectively dissipate heat and protect the normal operation of electronic equipment.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!