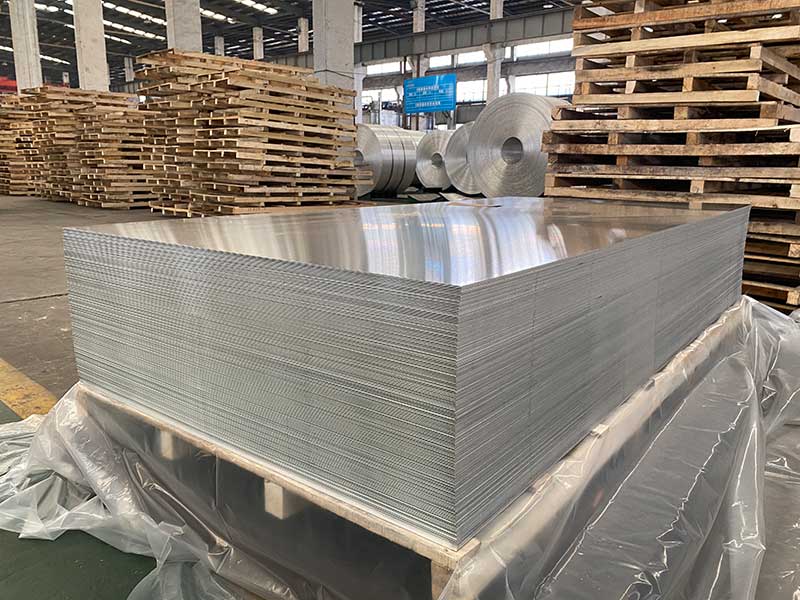

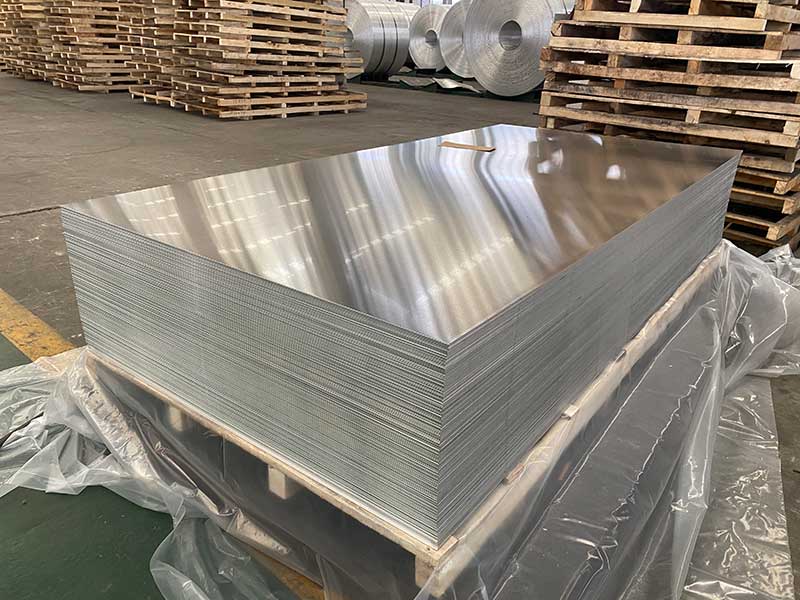

3105 Aluminum Sheet and Plate

3105 aluminum plate belongs to a series of AL-Mn alloys. It has good anti-rust properties and good electrical conductivity. The aluminum content is 98%. Due to the addition of 0.3% copper element, the electrical conductivity can reach 41%.

Email: export@xienuoenterprise.com

3105 Aluminum Sheet and Plate

3105 aluminum plate belongs to a series of AL-Mn alloys. It has good anti-rust properties and good electrical conductivity. The aluminum content is 98%. Due to the addition of 0.3% copper element, the electrical conductivity can reach 41%.

3105 Aluminum Sheet DC / CC Alloy Designation (For Reference)

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 3xxx Series | 3105 | 3105 | ENAW-3105 |

3105 Aluminum Sheet DC / CC Chemical Compositing

Chemical Composition conforms to Chinese, American and European standard specification (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti | Others:Each |

| 3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.4 | 0.2 | 0.1 | 0.05 |

Product Videos

Mechanical Properties Of 3105 Aluminum Sheet

3105 aluminum plate tensile strength 125-175 MPa

Elongation: > 1%

Compressive strength 110-145Mpa

3105 Aluminum Sheet DC / CC Available Size Range

| Alloy | 3105 Aluminum Sheet |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, T4, T6, T651. |

| Thickness(mm) | 0.2-10.0mm |

| Width(mm) | 500-2800mm |

| Standards | GB, EN, ASTM, AISI, JIS, DIN. |

| Surface Treatment | Anodizing, Color coating, Embossing, Lamination, Polishing etc. |

| Packaging | Standard export wooden box/pallet packaging, suitable for sea transportation |

3105 Aluminum Sheet CC / DC Temper (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

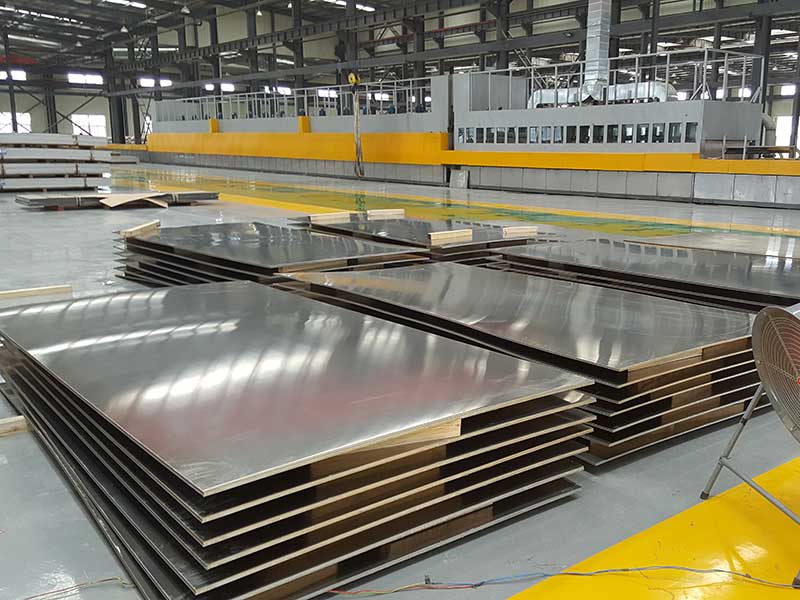

Characteristics Of 3105 Aluminum Sheet

3105 aluminum alloy aluminum plate has excellent corrosion resistance, excellent plasticity and process performance, and has excellent gas cutting and arc welding performance.

The compressive strength of 3105 aluminum is slightly higher than that of 3003 aluminum, and other properties are similar to 3003 aluminum alloy profiles.

3105 aluminum plate has high plasticity in the case of quenching. In semi-cold hardening, the plasticity is still stronger, low plasticity, excellent corrosion resistance, excellent electric welding weldability and poor drilling performance in the case of cold hardening.

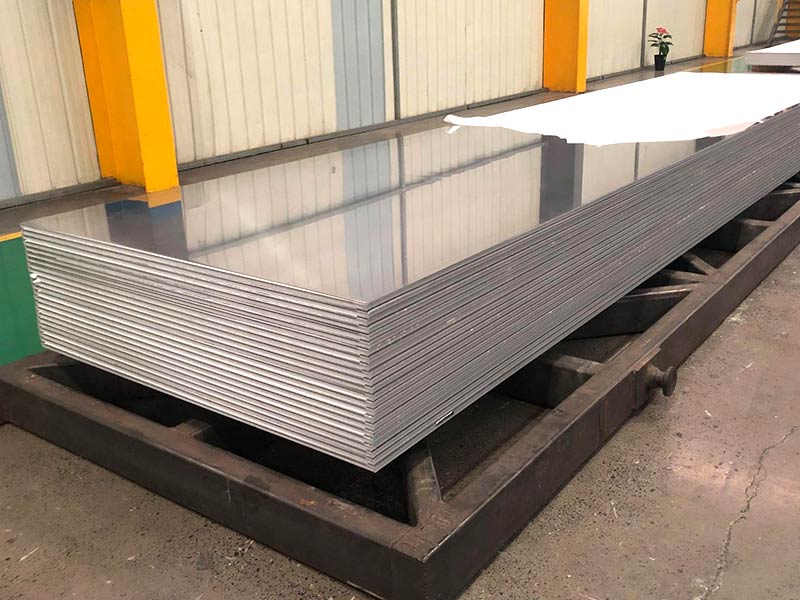

Application Of 3105 Aluminum Sheet

3105 aluminum alloy has high strength, light weight, and good waterproofing and earthquake resistance. 3105 aluminum plate is mainly used for bottle stoppers, beverage bottle caps, skin care product caps, etc.

Applications in the construction industry include room panels, partitions, movable room panels, binding lines and drainage pipes, plastic sheet forming components, etc.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!