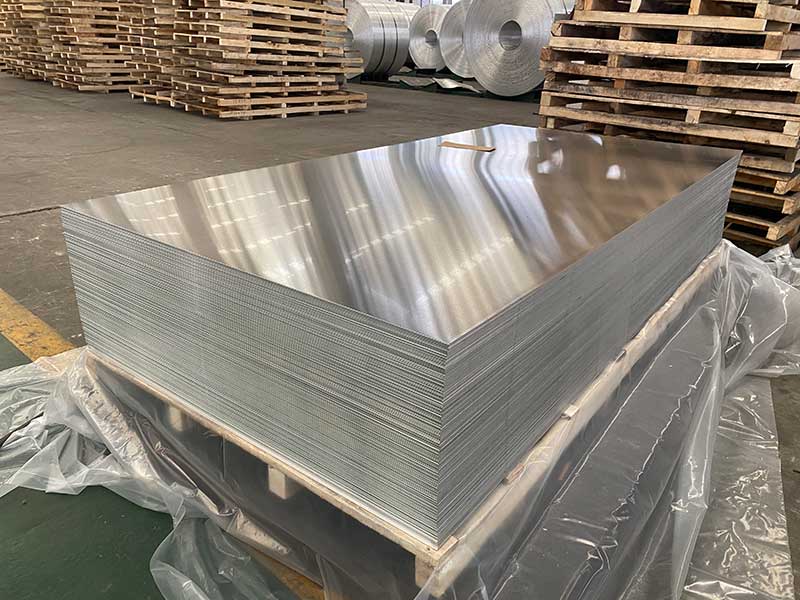

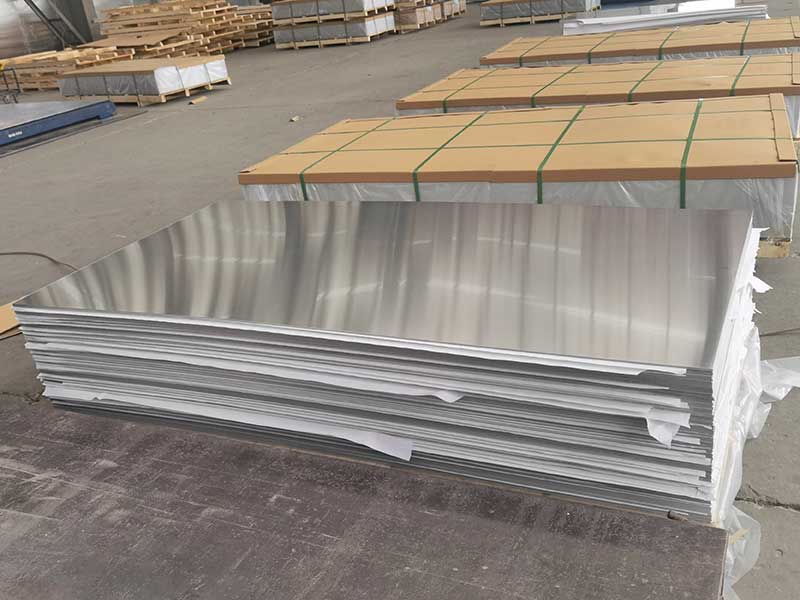

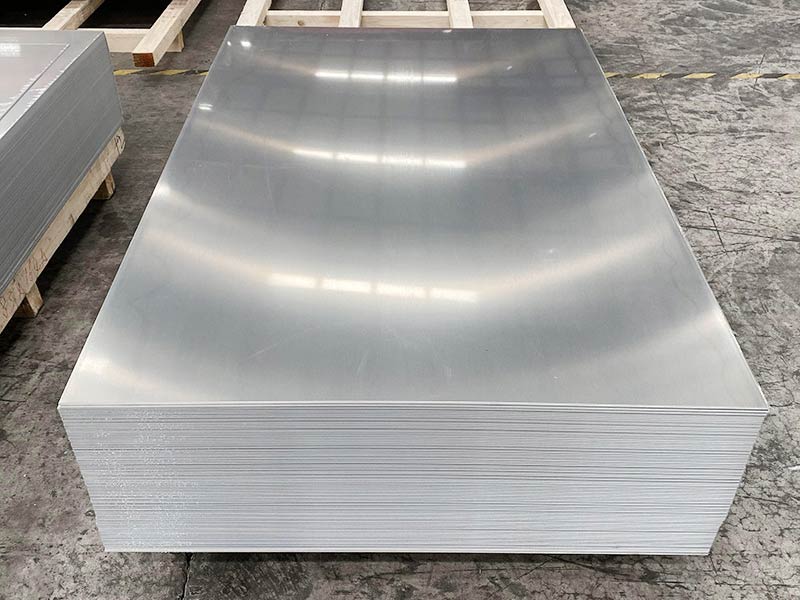

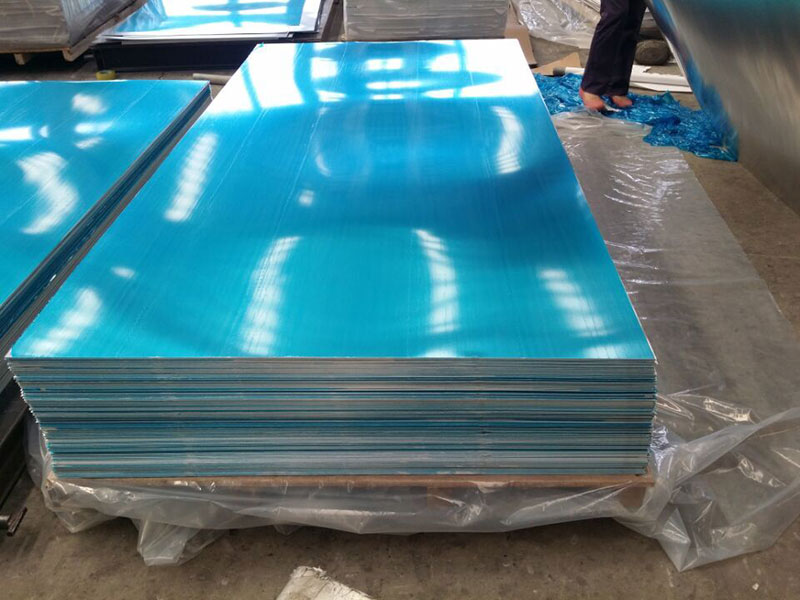

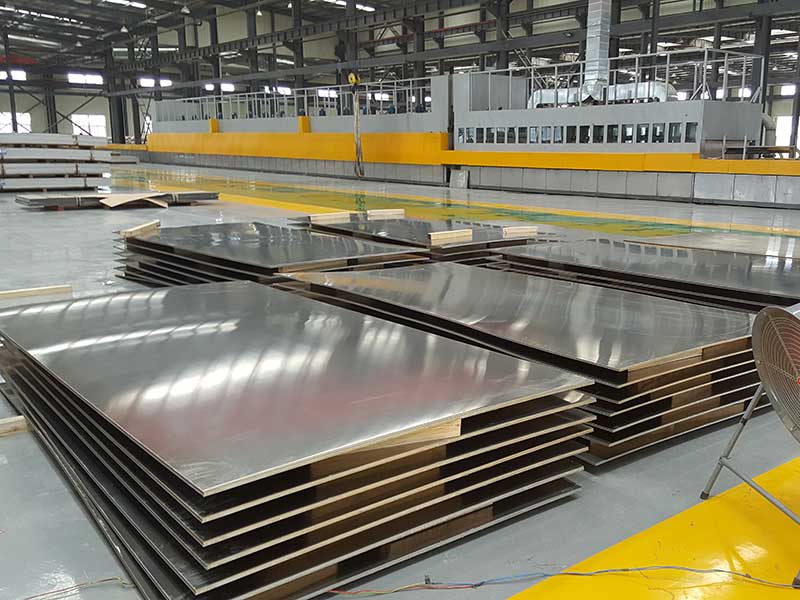

3004 Aluminum Sheet and Plate

3004 is an AL-Mn alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high (slightly higher than industrial pure aluminum) and cannot be strengthened by heat treatment, so cold working methods are used to improve its mechanical properties.

Email: export@xienuoenterprise.com

3004 Aluminum Sheet and Plate

3004 is an AL-Mn alloy, which is the most widely used anti-rust aluminum. The strength of this alloy is not high (slightly higher than industrial pure aluminum) and cannot be strengthened by heat treatment, so cold working methods are used to improve its mechanical properties.

It has high plasticity in the annealed state, good plasticity in semi-cold work hardening, low plasticity in cold work hardening, good corrosion resistance, good weldability, and poor machinability.

3004 Aluminum Sheet DC / CC Alloy Designation (For Reference)

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 3xxx Series | 3004 | 3004 | ENAW-3004 |

3004 Aluminum Sheet DC / CC Chemical Compositing

Chemical Composition conforms to Chinese, American and European standard specification (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Others:Each |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0-1.5 | 0.8-1.3 | 0.1 | 0.05 |

Product Videos

Mechanical Properties Of 3004 Aluminum Sheet

Tensile strength σb (MPa): 150~285

Elongation δ10 (%): 1~16

3004 Aluminum Sheet DC / CC Available Size Range

| Alloy | 3004 Aluminum Sheet |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, T4, T6, T651. |

| Thickness(mm) | 0.2-10.0mm |

| Width(mm) | 500-2800mm |

| Standards | GB, EN, ASTM, AISI, JIS, DIN. |

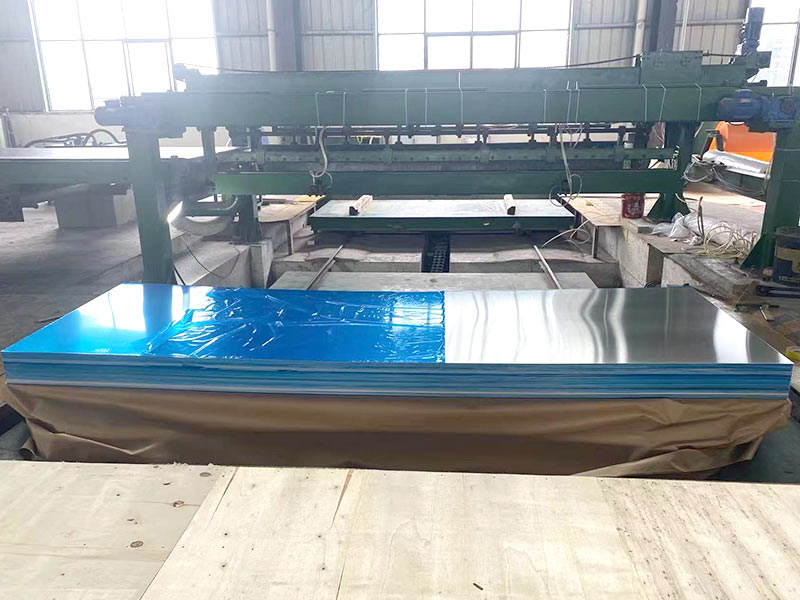

| Surface Treatment | Anodizing, Color coating, Embossing, Lamination, Polishing etc. |

| Packaging | Standard export wooden box/pallet packaging, suitable for sea transportation |

3004 Aluminum Sheet CC / DC Temper (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

Characteristics Of 3004 Aluminum Sheet

3004 alloy aluminum plate has the advantages of stable performance, high strength, oxidation resistance, good coloring, stamping resistance, high elongation strength, and not easy to crack, and has been unanimously recognized by the market.

Application Of 3004 Aluminum Sheet

3004 aluminum plate has good formability, weldability and corrosion resistance. Used for processing parts and components that require good formability, high corrosion resistance and good weldability, such as kitchen utensils, food and chemical product processing and storage devices, tanks and tanks for transporting liquid products, and various pressures for thin plate processing Containers and pipes, general utensils, heat sinks, cosmetic boards, photocopier rollers, ship materials

3004 aluminum sheets and strips are mainly used in chemical product production and storage devices, thin plate processing parts, building materials, building baffles, cable ducts, sewers, various lighting parts, beverage cans, corrugated sheets, building materials, colored aluminum plates, and lamp holders.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!