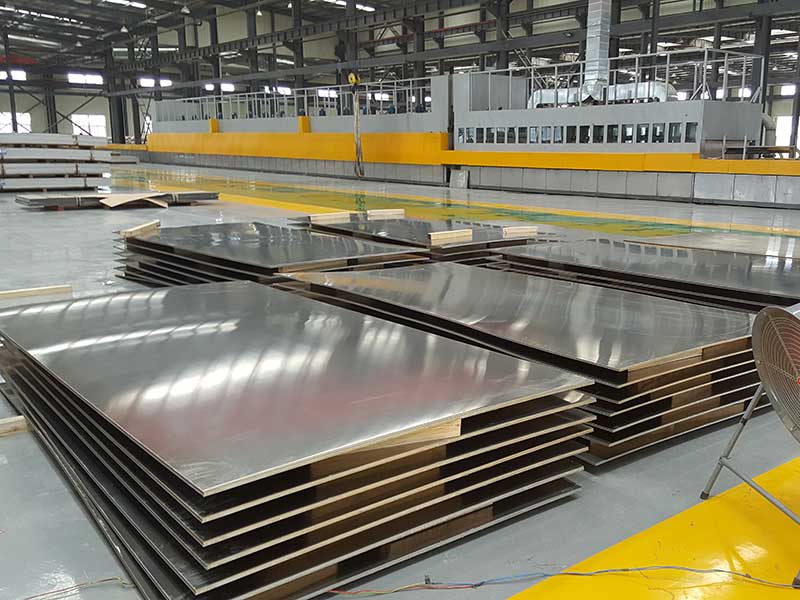

3003 Aluminum Sheet and Plate

3003 is an AL-Mn alloy and is the most widely used anti-rust aluminum. The strength of this alloy is not high (slightly higher than industrial pure aluminum) and cannot be strengthened by heat treatment, so cold working methods are used to improve its mechanical properties.

Email: export@xienuoenterprise.com

3003 Aluminum Sheet and Plate

3003 is an AL-Mn alloy and is the most widely used anti-rust aluminum. The strength of this alloy is not high (slightly higher than industrial pure aluminum) and cannot be strengthened by heat treatment, so cold working methods are used to improve its mechanical properties.

3003 Aluminum Sheet DC / CC Alloy Designation (For Reference)

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 3xxx Series | 3003 | 3003 | ENAW-3003 |

3003 Aluminum Sheet DC / CC Chemical Compositing

Chemical Composition conforms to Chinese, American and European standard specification (For Reference)

| Alloy | Si | Fe | Cu | Mn | Zn | Ti | Others:Each |

| 3003 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | 0.25 | 0.15 | 0.05 |

Product Videos

Mechanical Properties Of 3003 Aluminum Sheet

Tensile strength σb (MPa) 120-160

Conditional yield strength σ0.2 (MPa) ≥85

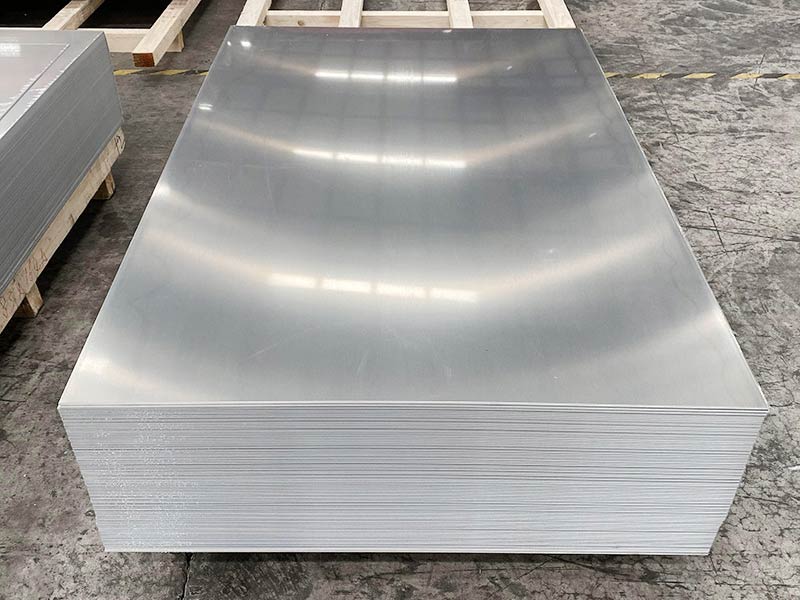

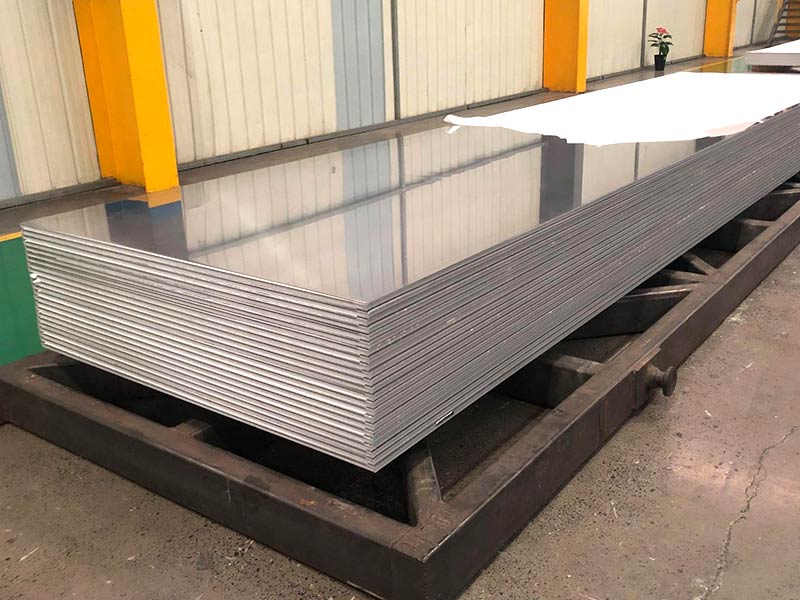

3003 Aluminum Sheet DC / CC Available Size Range

| Alloy | 3003 Aluminum Sheet |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, T4, T6, T651. |

| Thickness(mm) | 0.2-10.0mm |

| Width(mm) | 500-2800mm |

| Standards | GB, EN, ASTM, AISI, JIS, DIN. |

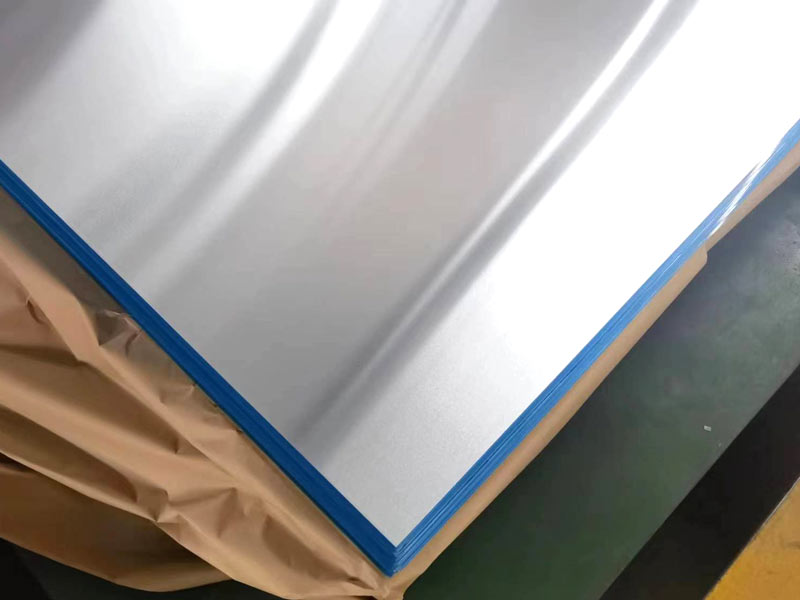

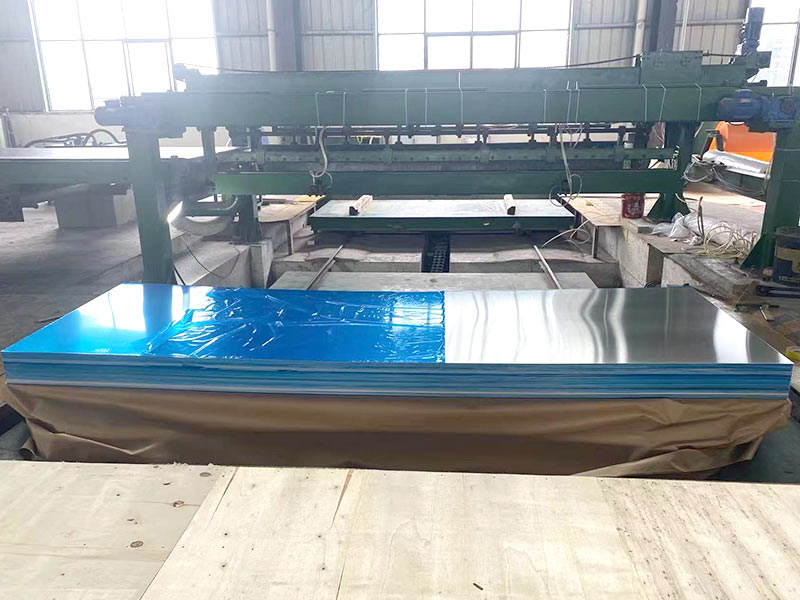

| Surface Treatment | Anodizing, Color coating, Embossing, Lamination, Polishing etc. |

| Packaging | Standard export wooden box/pallet packaging, suitable for sea transportation |

3003 Aluminum Sheet CC / DC Temper (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

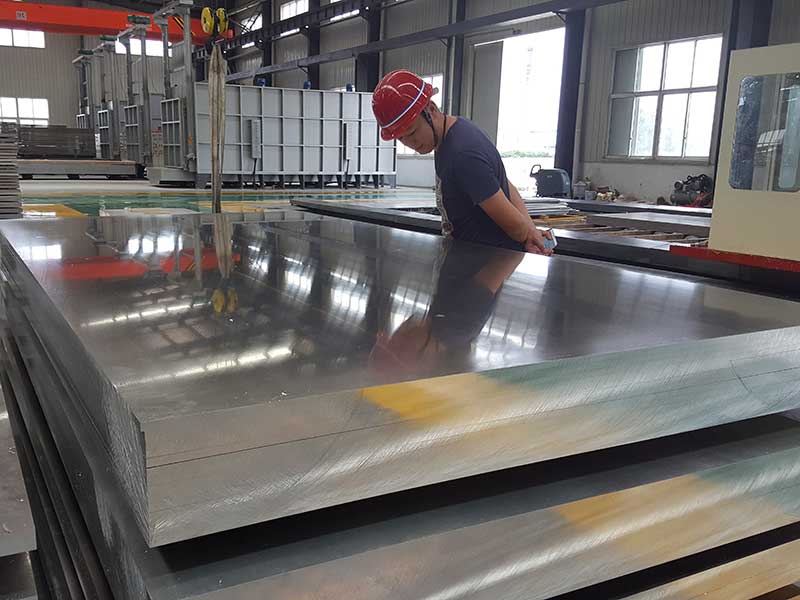

Characteristics Of 3003 Aluminum Sheet

1. High strength and good plasticity: 3003 aluminum plate has high strength and good plasticity, which can meet the processing needs of various complex shapes while ensuring the stability of the product structure.

2. Excellent corrosion resistance: By using advanced surface treatment technology, 3003 aluminum plates can effectively improve corrosion resistance, extend service life, and reduce maintenance costs.

3. Good electrical and thermal conductivity: 3003 aluminum plate has excellent electrical and thermal conductivity and is suitable for areas that require efficient heat transfer, such as radiators, electronic equipment, etc.

Application Of 3003 Aluminum Sheet

1. Construction field: Due to the high strength, light weight and beautiful surface treatment of 3003 aluminum plate, it is widely used in building curtain walls, roofs, interior decoration, etc. Its excellent corrosion resistance and long life provide architects and designers with more possibilities.

2. Packaging industry: 3003 aluminum plate has good moisture-proof, rust-proof and pressure-resistant properties, and is suitable for various packaging materials, such as food packaging, electronic product packaging, etc.

3. Transportation field: Due to its high strength and good corrosion resistance, 3003 aluminum plates are widely used in the manufacturing of parts for automobiles, trains, airplanes and other transportation vehicles.

4. Electronics and electrical appliances industry: Due to its excellent electrical and thermal conductivity, 3003 aluminum plates are widely used in the manufacturing of electronic equipment casings, circuit board brackets, radiators and other components.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!