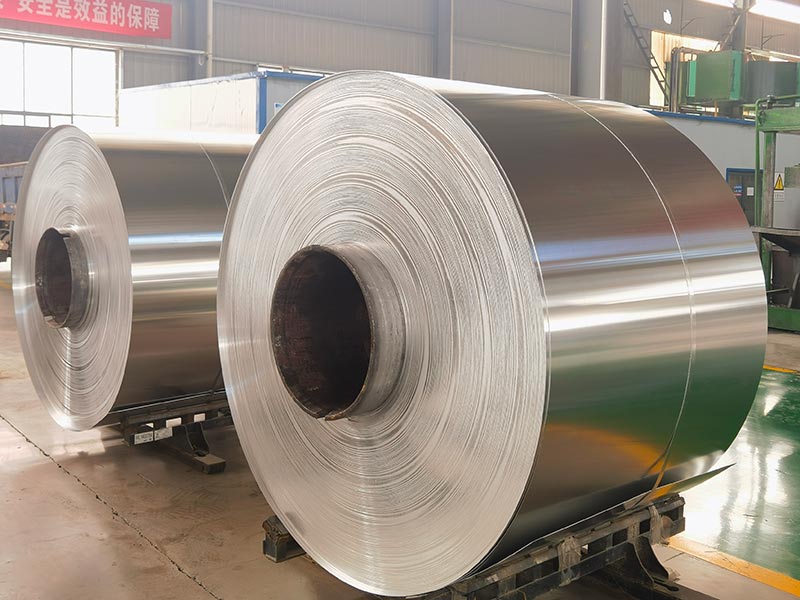

1100 Aluminum Coil and Strip

1100 is usually used for products that require good forming performance, high corrosion resistance, and do not require high strength, such as food and chemical handling and storage equipment, sheet metal products, hollow hardware processed by drawing and spinning, and welded combination keys. , reflectors, nameplates, etc.

Email: export@xienuoenterprise.com

1100 Aluminum Coil and Strip

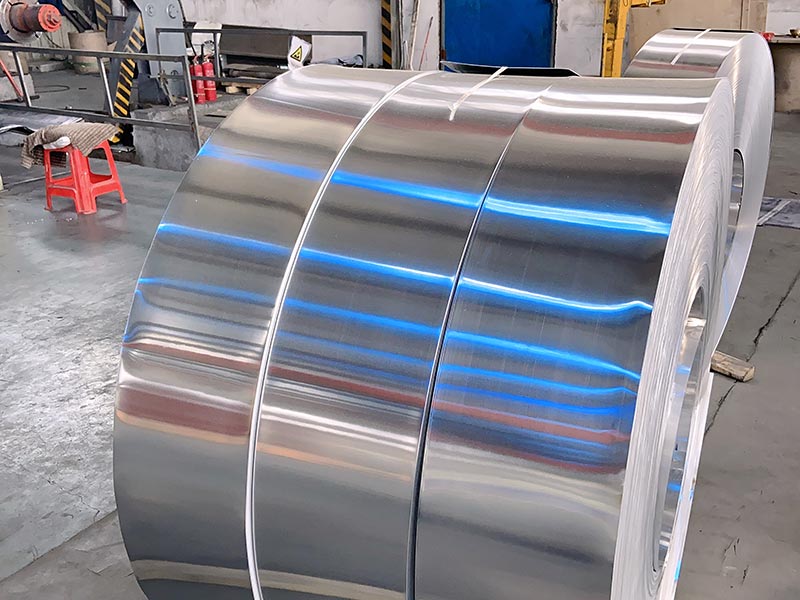

1100 pure aluminum coil is ordinary industrial pure aluminum containing 99.0% aluminum. It cannot be strengthened by heat treatment; its strength is low, but it has good ductility, formability, weldability and corrosion resistance; its corrosion resistance can be further improved after anodizing while obtaining a beautiful surface.

1100 Aluminum Coil DC / CC Temper designation (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

Product Videos

1100 Aluminum Coil DC / CC Chemical Compositing

| Alloy | SI | Fe | Cu | Mn | Zn | Others:Each | Others:Total | Al:Min. |

| 1100 | 0.95 Si + Fe | 0.05-0.20 | 0.05 | 0.1 | 0.05 | 0.15 | 99.0 | |

1100 Aluminum Coil DC / CC Available Size Range

| Alloy | 1100 |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, T4, T6, T651. |

| Thickness(mm) | 0.2-500 |

| Width(mm) | 100-2650 |

| Standards | GB, EN, ASTM, AISI, JIS, DIN. |

| Surface Treatment | Anodizing, Color coating, Embossing, Lamination, Polishing etc. |

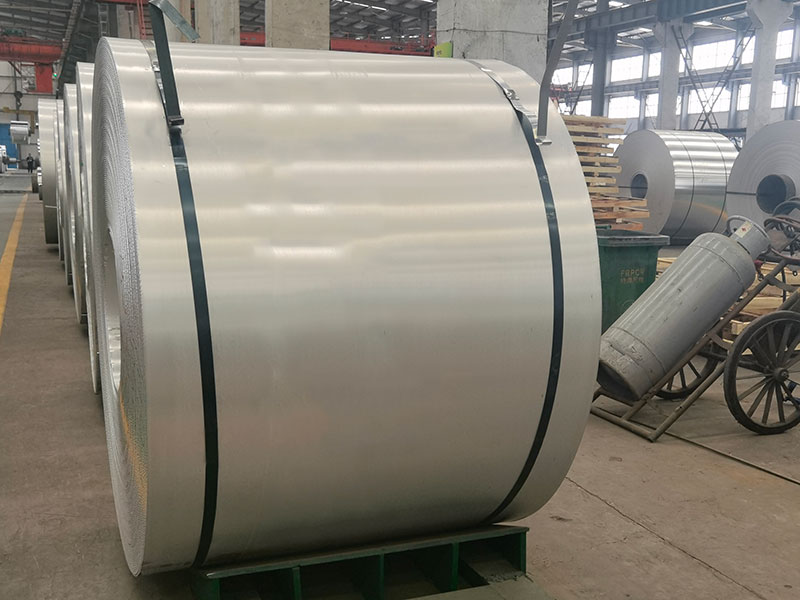

| Packaging | Standard export wooden box/pallet packaging, suitable for sea transportation |

Characteristics of 1100 aluminum coil

Mechanical properties: The tensile strength of 1100 aluminum coil is not less than 110MPa, the yield strength is not less than 90MPa, and the elongation is not less than 8%.

Corrosion resistance: The corrosion resistance of 1100 aluminum coils should meet the requirements of relevant product standards. In humid environments, aluminum coils should have certain corrosion resistance.

1100 Aluminum Coil DC / CC Application

1100 is usually used for products that require good forming performance, high corrosion resistance, and do not require high strength, such as food and chemical handling and storage equipment, sheet metal products, hollow hardware processed by drawing and spinning, and welded combination keys. , reflectors, nameplates, etc.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!