1070 Aluminum Sheet and Plate

1070 aluminum alloy has good processability, is easy to deep draw, spin and weld, and has excellent electrical conductivity. Due to its high purity, the strength and corrosion resistance of 1070 aluminum plate are relatively low, so it is not suitable for fields requiring high strength and corrosion resistance.

Email: export@xienuoenterprise.com

1070 Aluminum Sheet and Plate

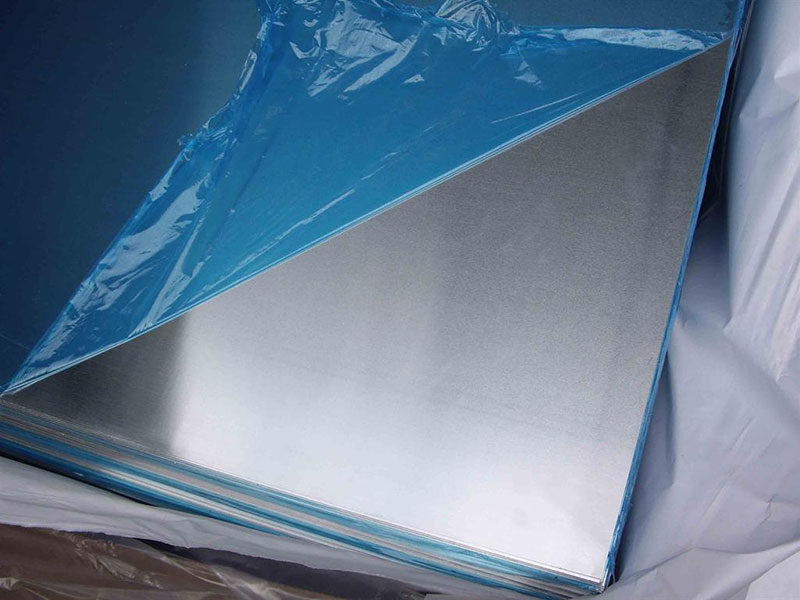

1070 Aluminum Sheet Plate

1070 aluminum alloy has good processability, is easy to deep draw, spin and weld, and has excellent electrical conductivity. Due to its high purity, the strength and corrosion resistance of 1070 aluminum plate are relatively low, so it is not suitable for fields requiring high strength and corrosion resistance.

Hot selling 1070 aluminum sheet plate

Xienuo can produce 1070 aluminum sheets plates with widths from 20mm to 2650mm and thicknesses from 0.1 to 500mm. Supports additional processes such as stamping, stretching, anodizing, plastic film coating, color coating, paper clamping, sand blast, embossed, etching, etc.

Xienuo has 25 years of experience in producing 1000 series aluminum sheets plates. In addition to 1070 aluminum plates, it also provides 1050, 1060, 1100, 1200 and 1235 aluminum plates. Welcome to inquire.

Alloy:1070

Temper: O,H112,H12,H14,H16,H18,H22,H24,H26,H28,F

Thickness:0.1mm-500mm

Width:20mm-2650mm

Regular width:1000/1220/1250/1500/2000mm/2650mm

Length: Up to 16000 mm

Regular Length:2000/2440mm/3000/6000/16000mm

Standard: AISI, ASTM, DIN, JIS, GB, EN, etc.

Surface : Bright, polished, hair line, brush, sand blast, embossed, etching, etc.

Finish :Mill, Customer specific finish

Aluminum Sheet/ Plate Coating : PVC Coated, Color Coated, Polyester, Fluorocarbon, polyurethane and epoxy coating

Type : Hot-Rolled (HR) / Cold-Rolled (CR) Sheet

MOQ: Generally, the trial order will be accepted.

HS code:76061199

Lead Time:7-35 days delivery, global export

Price Term: CIF CFR FOB EX-WORK or according to negotiation

Payment Term: TT, LC at sight or according to negotiation

Packaging and packing : Standard seaworthy export packaging. With protection(covering with brown paper and plastic film).

Supply Ability:10, 000 tons per Month

Standard Specification for Aluminium 1070 Sheets

ASTM B209 - Standard Specification for Aluminum and Aluminum-Alloy Sheets

ASTM B632 / B632M -Standard Specification for Aluminum-Alloy Rolled Tread Sheets

ASTM B947 - Standard Practice for Hot Rolling Mill Solution Heat Treatment for Aluminum Alloy Sheets

ASTM B548 - Standard Test Method for Ultrasonic Inspection of Aluminum-Alloy Sheets for Pressure Vessels

AMS 4001 - Aluminum Sheet, 0.12Cu (1100-0), Annealed

AMS 4003 - Aluminum Alloy, Sheet, 0.12cu (1100-H14), Strain Hardened

AMS QQA250/1 - Aluminum 1100 Sheet

1070 Aluminum equivalent grades

| EN | GB | JIS | India | UNS | ISO | DIN |

| EN AW-1070/Al99,7 | 1070 | A1070 | 19700 | A91070 | A99.7 | A199.7 |

1070 chemical properties

| Alloy | 1070 |

| Aluminum (Al), % | 99.7 to 100 |

| Copper (Cu), % | 0 to 0.040 |

| Iron (Fe), % | 0 to 0.25 |

| Magnesium (Mg), % | 0 to 0.030 |

| Manganese (Mn), % | 0 to 0.030 |

| Silicon (Si), % | 0 to 0.2 |

| Titanium (Ti), % | 0 to 0.030 |

| Vanadium (V), % | 0 to 0.050 |

| Zinc (Zn), % | 0 to 0.040 |

| Other, each | 0 to 0.03 |

Properties

1070 O Aluminum Mechanical Properties

| Elastic (Young's, Tensile) Modulus | 68 GPa | 9.9 x psi |

| Elongation at Break | 39 % | |

| Fatigue Strength | 22 MPa | 3.2 x psi |

| Poisson's Ratio | 0.33 | |

| Shear Modulus | 26 GPa | 3.7 x psi |

| Shear Strength | 50 MPa | 7.2 x psi |

| Tensile Strength: Ultimate (UTS) | 73 MPa | 11 x psi |

| Tensile Strength: Yield (Proof) | 17 MPa | 2.5 x psi |

Common Calculations

| Resilience: Ultimate (Unit Rupture Work) | 21 MJ/m3 |

| Resilience: Unit (Modulus of Resilience) | 2.1 kJ/m3 |

| Stiffness to Weight: Axial | 14 points |

| Stiffness to Weight: Bending | 50 points |

| Strength to Weight: Axial | 7.5 points |

| Strength to Weight: Bending | 14 points |

| Thermal Diffusivity | 94 mm2/s |

| Thermal Shock Resistance | 3.3 points |

1070 H112 Aluminum

Mechanical Properties

| Elastic (Young's, Tensile) Modulus | 68 GPa | 9.9 x psi |

| Elongation at Break | 17 % | |

| Fatigue Strength | 36MPa | 5.2 x psi |

| Poisson's Ratio | 0.33 | |

| Shear Modulus | 26 GPa | 3.7 x psi |

| Shear Strength | 48 MPa | 7 x psi |

| Tensile Strength: Ultimate (UTS) | 78 MPa | 11 x psi |

| Tensile Strength: Yield (Proof) | 40MPa | 5.8 x psi |

Common Calculations

| Resilience: Ultimate (Unit Rupture Work) | 11 MJ/m3 |

| Resilience: Unit (Modulus of Resilience) | 12 kJ/m3 |

| Stiffness to Weight: Axial | 14 points |

| Stiffness to Weight: Bending | 50 points |

| Strength to Weight: Axial | 8 points |

| Strength to Weight: Bending | 15 points |

| Thermal Diffusivity | 94 mm2/s |

| Thermal Shock Resistance | 3.5 points |

1070 H12 H22 Aluminum

Mechanical Properties

| Elastic (Young's, Tensile) Modulus | 68 GPa | 9.9 x psi |

| Elongation at Break | 10% | |

| Fatigue Strength | 48MPa | 6.9 x psi |

| Poisson's Ratio | 0.33 | |

| Shear Modulus | 26 GPa | 3.7 x psi |

| Shear Strength | 53 MPa | 7.6 x psi |

| Tensile Strength: Ultimate (UTS) | 88 MPa | 13 x psi |

| Tensile Strength: Yield (Proof) | 63MPa | 9.1 x psi |

Common Calculations

| Resilience: Ultimate (Unit Rupture Work) | 8.0 MJ/m3 |

| Resilience: Unit (Modulus of Resilience) | 29 kJ/m3 |

| Stiffness to Weight: Axial | 14 points |

| Stiffness to Weight: Bending | 50 points |

| Strength to Weight: Axial | 9.1 points |

| Strength to Weight: Bending | 16 points |

| Thermal Diffusivity | 94 mm2/s |

| Thermal Shock Resistance | 3.9 points |

1070 H14 H24 Aluminum

Mechanical Properties

| Elastic (Young's, Tensile) Modulus | 68 GPa | 9.9 x psi |

| Elongation at Break | 6.7% | |

| Fatigue Strength | 38MPa | 5.5 x psi |

| Poisson's Ratio | 0.33 | |

| Shear Modulus | 26 GPa | 3.7 x psi |

| Shear Strength | 59 MPa | 8.6 x psi |

| Tensile Strength: Ultimate (UTS) | 100 MPa | 15 x psi |

| Tensile Strength: Yield (Proof) | 74MPa | 11 x psi |

Common Calculations

| Resilience: Ultimate (Unit Rupture Work) | 6.2 MJ/m3 |

| Resilience: Unit (Modulus of Resilience) | 40 kJ/m3 |

| Stiffness to Weight: Axial | 14 points |

| Stiffness to Weight: Bending | 50 points |

| Strength to Weight: Axial | 10 points |

| Strength to Weight: Bending | 18 points |

| Thermal Diffusivity | 94 mm2/s |

| Thermal Shock Resistance | 4.5 points |

1070 H16 H26 Aluminum

Mechanical Properties

| Elastic (Young's, Tensile) Modulus | 68 GPa | 9.9 x psi |

| Elongation at Break | 4.5% | |

| Fatigue Strength | 37MPa | 5.4 x psi |

| Poisson's Ratio | 0.33 | |

| Shear Modulus | 26 GPa | 3.7 x psi |

| Shear Strength | 67 MPa | 9.8 x psi |

| Tensile Strength: Ultimate (UTS) | 120 MPa | 17 x psi |

| Tensile Strength: Yield (Proof) | 86MPa | 12 x psi |

Common Calculations

| Resilience: Ultimate (Unit Rupture Work) | 4.8 MJ/m3 |

| Resilience: Unit (Modulus of Resilience) | 54 kJ/m3 |

| Stiffness to Weight: Axial | 14 points |

| Stiffness to Weight: Bending | 50 points |

| Strength to Weight: Axial | 12 points |

| Strength to Weight: Bending | 20 points |

| Thermal Diffusivity | 94 mm2/s |

| Thermal Shock Resistance | 5.2 points |

1070 H18 H28 Aluminum

Mechanical Properties

| Elastic (Young's, Tensile) Modulus | 68 GPa | 9.9 x psi |

| Elongation at Break | 4.5% | |

| Fatigue Strength | 46MPa | 6.7 x psi |

| Poisson's Ratio | 0.33 | |

| Shear Modulus | 26 GPa | 3.7 x psi |

| Shear Strength | 79 MPa | 11 x psi |

| Tensile Strength: Ultimate (UTS) | 140 MPa | 20 x psi |

| Tensile Strength: Yield (Proof) | 120MPa | 17 x psi |

Common Calculations

| Resilience: Ultimate (Unit Rupture Work) | 5.9 MJ/m3 |

| Resilience: Unit (Modulus of Resilience) | 110 kJ/m3 |

| Stiffness to Weight: Axial | 14 points |

| Stiffness to Weight: Bending | 50 points |

| Strength to Weight: Axial | 14 points |

| Strength to Weight: Bending | 22 points |

| Thermal Diffusivity | 94 mm2/s |

| Thermal Shock Resistance | 6.1 points |

Other properties of 1070

Basic Properties

| Density | 2.7 g/cm3 | 170 lb/ft3 |

| Embodied Carbon | 8.3 kg CO2/kg material | |

| Embodied Energy | 160 MJ/kg | 67 x BTU/lb |

| Embodied Water | 1200 L/kg | 140 gal/lb |

Thermal Properties

| Latent Heat of Fusion | 400 J/g | |

| Maximum Temperature: Mechanical | 170 °C | 340 °F |

| Melting Completion (Liquidus) | 640 °C | 1190 °F |

| Melting Onset (Solidus) | 640 °C | 1180 °F |

| Specific Heat Capacity | 900 J/kg-K | 0.22 BTU/lb-°F |

| Thermal Conductivity | 230 W/m-K | 130 BTU/h-ft-°F |

| Thermal Expansion | 23 µm/m-K | |

Electrical Properties

| Electrical Conductivity: Equal Volume | 61 % IACS |

| Electrical Conductivity: Equal Weight (Specific) | 200 % IACS |

1070 aluminum alloy product characteristics

Low density, good electrical and thermal conductivity

Good corrosion resistance and good plastic processing performance

Can be welded, such as gas welding, argon arc welding, spot welding, etc.

It cannot be strengthened by heat treatment, but its strength can be improved by cold deformation and annealing.

1070 Aluminum Sheet Heat Treatment Process

Complete annealing

Heating to 390 ~ 430 °C;

Depending on the thickness of the material, the holding time should be controlled from 30 to 120 minutes

The temperature decreases at a rate of 30 ~ 50 °C/H. When the temperature of the furnace is cooled to 300 °C, then air-cooled.

Rapid annealing

Heating to 350 ~ 370 °C;

Depending on the thickness of the material, the holding time should be 30 ~ 120 min, air or water cooling

Quenching and aging

Quenching at 500 ~ 510 °C, air cooling;

Artificial aging was 95 ~ 105 °C, 3H, air cooling;

Natural aging-room temperature 120H

1070 aluminum sheet plate application

1070 aluminum plates are used in products that do not require high strength. Common application fields include 3C electronics, aerospace, construction, etc.

1. Electronic field, such as manufacturing mats and capacitors, tube isolation nets, wires, etc.

2. Aerospace field, such as aircraft ventilation system parts and decorative parts, etc.

3. Construction field, such as curtain wall materials, windows, doors, roof materials, ceilings, etc.

1070 aluminum sheet packaging

1. Plastic or kraft paper packages protect against moisture and rain and contain a desiccant

2. Packed in wooden pallets or wooden boxes and fixed with steel straps

3. Wooden pallets or wooden boxes have fumigation marks

4. Packaging according to customers' other packaging requirements

1070 aluminum sheet plate price

1070 aluminum sheet plate price calculation method: SMM A00 aluminum ingot price + processing fee + freight = 1070 aluminum sheet plate price (yuan/ton)

1070 aluminum plate aluminum plate weight (kg) = 0.00271 × thickness × width × length

SMM A00 aluminum ingot price: It is usually settled based on the aluminum ingot price on the day. It also supports the average price of aluminum ingots in the previous three days or the previous five days.

Processing fee: The processing techniques of 1070 aluminum plates in different states are different, so the processing fee is also different.

Freight: Under normal circumstances, we contact the freight forwarder to deliver the goods, or you can designate a freight forwarding company to deliver the goods. Shipping costs will be informed to you in advance.

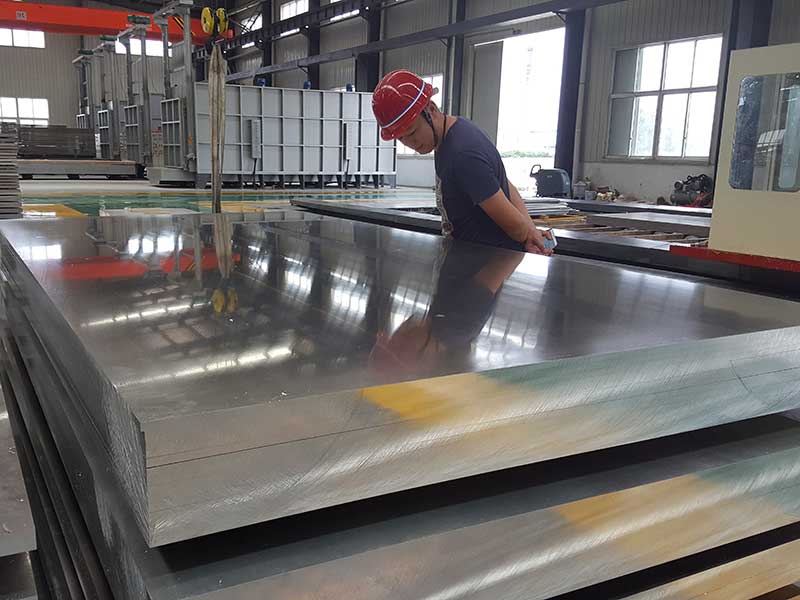

Why choose us?

Xienuo Enterprise has focused on the R&D and production of cold-rolled or hot-rolled 1070 aluminum plates for 25 years. It has an internationally advanced "1+4" hot rolling production line with high production efficiency. The price of 1070 aluminum plates is competitive. Welcome to inquire! In addition, we also produce 1070 aluminum coils, 1070 aluminum strips, 1070 anodized aluminum sheets, 1070 color-coated aluminum sheets, 1070 color-coated aluminum coils, etc.

Our advantage:

1. Produced in strict accordance with customer needs and guaranteed quality

2. Support third-party inspection and video inspection

3. Complete return and exchange policy

4. Rapid production and short delivery time

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!