1060 Aluminum Sheet and Plate

1060 aluminum is a pure aluminum that belongs to the 1000 series. 1060 is the Aluminum Association’s (AA) designation for this material. In the European standard it will be designated EN AW-1060. A91060 is the UNS number. Additionally, the EN chemical name is Al99,6.

Email: export@xienuoenterprise.com

1060 Aluminum Sheet and Plate

What is 1060 aluminum sheet plate?

1060 aluminum is a pure aluminum that belongs to the 1000 series. 1060 is the Aluminum Association’s (AA) designation for this material. In the European standard it will be designated EN AW-1060. A91060 is the UNS number. Additionally, the EN chemical name is Al99,6.

1060 aluminum has high plasticity, corrosion resistance, electrical conductivity and thermal conductivity, but low strength, cannot be strengthened by heat treatment, and has poor machinability; it can be gas welded, hydrogen atomic welded and contact welded, but not easy to braze; it can easily withstand various pressures Processing and stretching and bending.

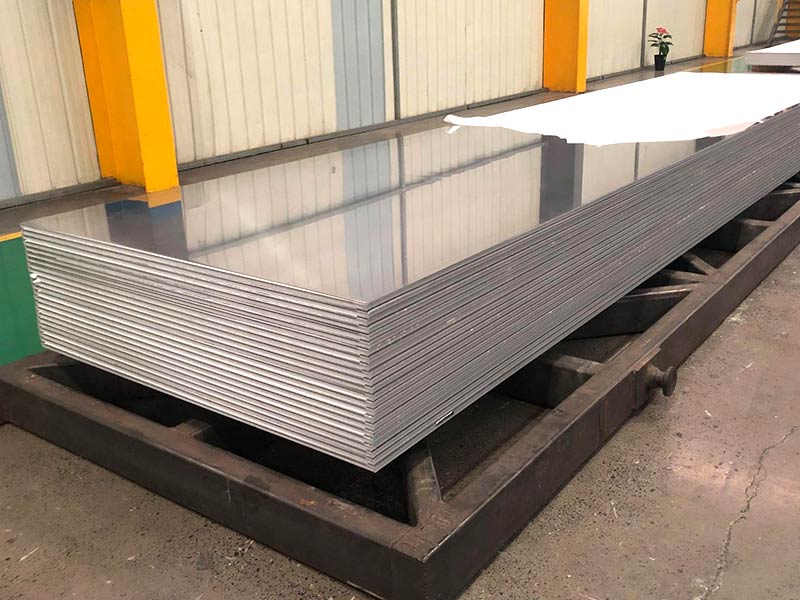

Hot selling 1060 aluminum sheet and plate

| Alloy | 1060 |

| Temper | O,H12,H14,H16 |

| Thickness | 0.016mm-6mm |

| Width | 100mm-2650mm |

| Length | 500mm-16000mm |

| Delivery time | 7-35 days |

| Executable standards: | National standard, American standard,European standard, Russian standard, Japanese standard, etc. |

| Application | Aluminum busbar, battery ear material, heat shield, decoration |

Product Videos

1060 chemical properties

| Alloy | 1060 |

| Aluminum (Al), % | 99.6 to 100 |

| Copper (Cu), % | 0 to 0.050 |

| Iron (Fe), % | 0 to 0.35 |

| Magnesium (Mg), % | 0 to 0.030 |

| Manganese (Mn), % | 0 to 0.030 |

| Silicon (Si), % | 0 to 0.25 |

| Titanium (Ti), % | 0 to 0.030 |

| Vanadium (V), % | 0 to 0.050 |

| Zinc (Zn), % | 0 to 0.050 |

Properties

The properties of 1060 mainly include mechanical properties, thermal properties, and electrical conductivity properties. The performance of 1060 aluminum sheets and plates in different states is different. Here, I will list the performance range of 1060 aluminum sheets and plates:

Mechanical Properties

| Alloy | 1060 |

| Elastic (Young's, Tensile) Modulus, GPa | 68 |

| Elongation at Break, % | 1.1 to 30 |

| Fatigue Strength, MPa | 15 to 50 |

| Poisson's Ratio | 0.33 |

| Shear Modulus, GPa | 26 |

| Shear Strength, MPa | 42 to 75 |

| Tensile Strength: Ultimate (UTS), MPa | 67 to 130 |

| Tensile Strength: Yield (Proof), MPa | 17 to 110 |

Thermal Properties

| Alloy | 1060 |

| Latent Heat of Fusion, J/g | 400 |

| Maximum Temperature: Mechanical, °C | 170 |

| Melting Completion (Liquidus), °C | 660 |

| Melting Onset (Solidus), °C | 650 |

| Specific Heat Capacity, J/kg-K | 900 |

| Thermal Conductivity, W/m-K | 230 |

| Thermal Expansion, µm/m-K | 24 |

Electrical Properties

| Alloy | 1060 |

| Electrical Conductivity: Equal Volume, % IACS | 62 |

| Electrical Conductivity: Equal Weight (Specific), % IACS | 210 |

Other Properties

| Alloy | 1060 |

| Base Metal Price, % relative | 9.5 |

| Calomel Potential, mV | -750 |

| Density, g/cm3 | 2.7 |

| Embodied Carbon, kg CO2/kg material | 8.3 |

| Embodied Energy, MJ/kg | 160 |

| Embodied Water, L/kg | 1200 |

Common Calculations

| Alloy | 1060 |

| Resilience: Ultimate (Unit Rupture Work), MJ/m3 | 0.57 to 37 |

| Resilience: Unit (Modulus of Resilience), kJ/m3 | 2.1 to 89 |

| Stiffness to Weight: Axial, points | 14 |

| Stiffness to Weight: Bending, points | 50 |

| Strength to Weight: Axial, points | 6.9 to 13 |

| Strength to Weight: Bending, points | 14 to 21 |

| Thermal Diffusivity, mm2/s | 96 |

| Thermal Shock Resistance, points | 3.0 to 5.6 |

1060 common temper

The common states of 1060 aluminum plate include 0, H112, H12, H14, H16, H18, H22, H24, H26, H28, etc. The mechanical properties of different states are different.

1. 1060-H12 Aluminum, strength is approximately one-quarter between annealed (O) and fully hard (H18)

2. 1060-H14 Aluminum, the strength is approximately between annealed (O) and full hard (H18)

3. 1060-H16 Aluminum, metal strain hardened to approximately 3/4 of the strength between annealed (O) and fully hard (H18)

4. 1060-H18 Aluminum, the strongest temper produced by strain hardening alone

5. 1060-H22 Aluminum, the metal is strain hardened and has about one-quarter the strength between annealed (O) and fully hard (H18).

6. 1060-H24 Aluminum, the strength is approximately between annealed (O) and full hard (H28)

7. 1060-H26 Aluminum, the metal is strain hardened to approximately 3/4 of the strength between annealed (O) and fully hard (H28).

8. 1060-H28 Aluminum, the strongest temper produced by the action of strain hardening followed by partial annealing. It is closely related to H18

9. 1060-O Aluminum, fully annealed, it has the highest ductility

Mechanical properties of 1060 aluminum plate in different states

| Alloy-temper | Specified | Tensile Strength | Yield Strength | Elongation |

| thickness(in) | (ksi) | (ksi) | (%) | |

| 1060-O | 0.006-0.019 | 8.0-14.0 | 2.5 | as low as 15 |

| 0.020-0.050 | as low as 22 | |||

| 0.051-3.000 | as low as 25 | |||

| 1060-H12 / 1060-H22 |

0.017-0.050 | 11.0-16.0 | 9.0 | as low as 6 |

| 0.051-2.000 | as low as 12 | |||

| 1060-H14 / 1060-H24 |

0.006-0.019 | 12.0-17.0 | 10.0 | as low as 1 |

| 0.020-0.050 | as low as 5 | |||

| 0.051-1.000 | as low as 10 | |||

| 1060-H16 / 1060-H26 |

0.006-0.019 | 14.0-19.0 | 11.0 | as low as 1 |

| 0.020-0.050 | as low as 4 | |||

| 0.051-0.162 | as low as 5 | |||

| 1060-H18 / 1060-H28 |

0.006-0.019 | as low as 16.0 | Min12.0 | as low as 1 |

| 0.020-0.050 | as low as 3 | |||

| 0.051-0.128 | as low as 4 | |||

| 1060-H112 | 0.250-0.499 | as low as 11.0 | as low as7.0 | as low as 10 |

| 0.500-1.000 | as low as 10.0 | as low as 5.0 | as low as 20 | |

| 1.001-3.000 | as low as 9.0 | as low as 4.0 | as low as 25 |

1060 aluminum sheet and plate hardness comparison table

| Temper | Hardness value [Wechsler hardness] |

| 1060 aluminum sheet H18 | 26-30 |

| 1060 aluminum sheet H24 | 22-26 |

| 1060 aluminum sheet O | 10-16 |

| 1060 aluminum sheet H22 | 12-16 |

1060 aluminum sheet plate application

1. Architectural decoration field, such as roofs, curtain wall panels, ceilings, windows

2. Electronic and electrical fields, capacitor casings, battery casings, radiators and electronic components

3. Transportation field, transportation vehicle shells, bodies, structural parts, etc.

4. Packaging field, beverage cans and sealing caps.

5. Home decoration field, such as furniture, lamps and other home decorations.

6. Other fields, such as manufacturing molds, die castings, chemical containers, etc.

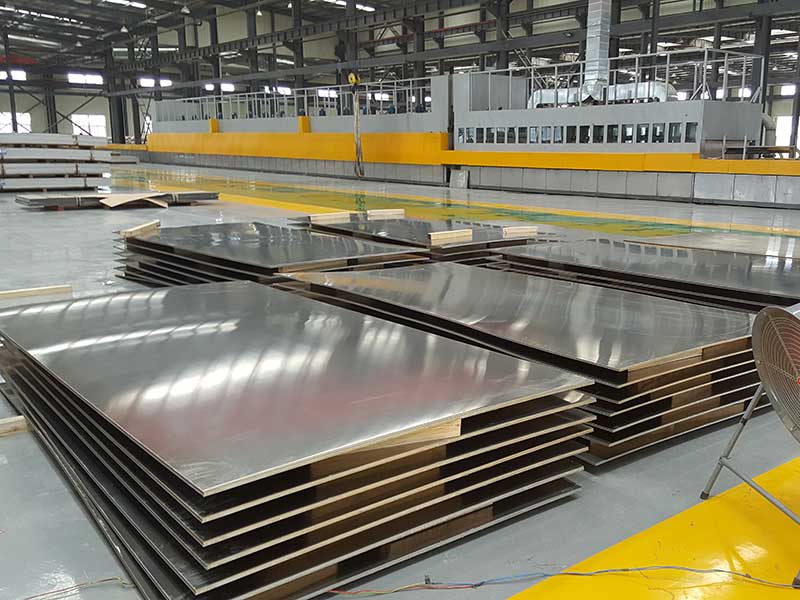

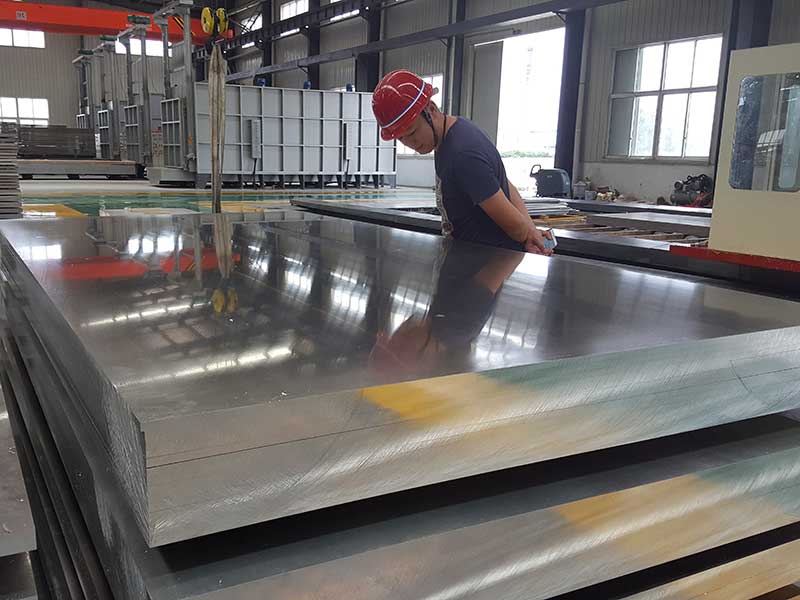

Why choose us?

Xienuo Enterprise has focused on the R&D and production of cold-rolled or hot-rolled 1060 aluminum plates for 25 years. It has an internationally advanced "1+4" hot rolling production line and is produced in strict accordance with the standards agreed with customers. The 1060 aluminum plates we produce have high surface gloss and are alkali-resistant. The washing effect is good and can reach level A in the water brushing test. Support third-party inspection to ensure compliance with customer requirements. In addition, Xienuo can meet conventional processing needs, such as stamping, stretching, anodizing, coating, etc.

Advanced equipment

Xienuo Enterprise introduced German SMS six-high cold rolling mill. The production of ultra-wide and ultra-thick 1060 aluminum plates eliminates internal stress and does not deform when cut. The width can be 2650mm and the thickness can be 500mm. It can produce ultra-wide and ultra-thick aluminum plates.

Complete products

Xienuo Enterprise not only produces 1060 aluminum plates, but also 1060 aluminum coils, aluminum strips, aluminum rods, aluminum tubes and other products with complete specifications to meet your one-stop shopping needs.

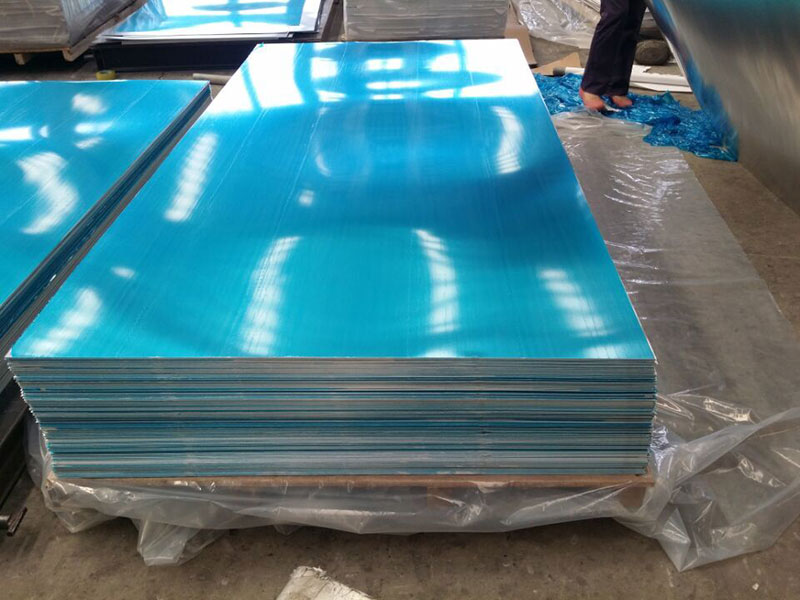

Perfect packaging

1. Clamp paper or film on the aluminum plate to ensure that the surface of the aluminum plate is intact and without scratches;

2. Plastic or kraft paper wrapping is used to prevent moisture and rain, ensuring that the aluminum plate is clean and free of dirt during transportation.

3. Each package has moisture-proof desiccant

4. Install wooden pallets and reinforce them with steel strips to avoid collision during transportation and ensure that the geometric shape of the aluminum plate remains unchanged;

5. Export products are packaged in wooden boxes and pallets with fumigation marks;

6. Packaging according to other packaging requirements of customers;

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!