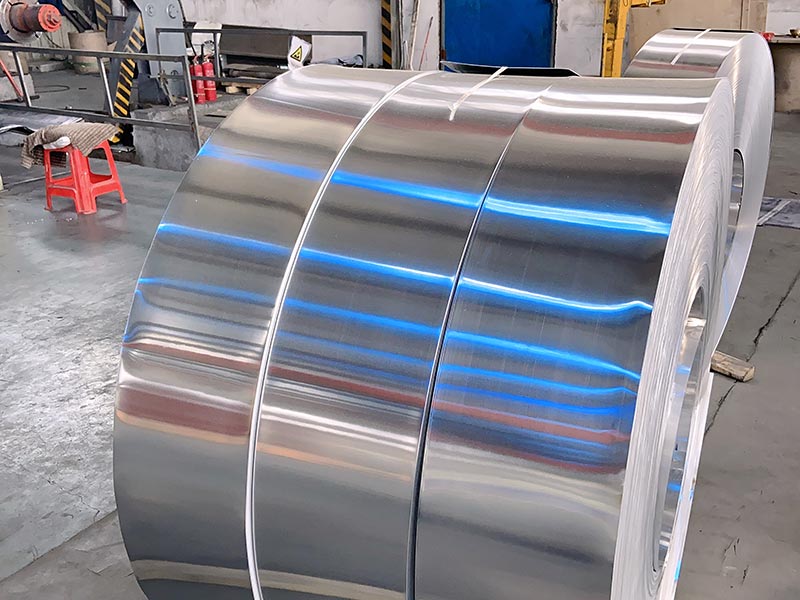

1060 Aluminum Coil and Strip

1060 aluminum coil has the characteristics of high purity, lightness, good thermal conductivity, good electrical conductivity, and stable processing performance. It is widely used in construction, aviation, electronics, automobiles and other fields, and is a very important aluminum alloy material.

Email: export@xienuoenterprise.com

1060 Aluminum Coil and Strip

1060 aluminum alloy is a pure aluminum material containing elements such as copper, manganese, magnesium, and silicon. It is an aluminum alloy with high purity, high toughness and good weldability, and is widely used in various industrial fields. In our country, 1060 aluminum alloy is one of the most widely used aluminum alloy materials in industrial production.

1060 Aluminum Coil DC / CC Chemical Compositing

The composition of 1060 aluminum is relatively simple compared to other aluminum alloys. The main component is aluminum element (Al), and its purity reaches more than 99.6%. 1060 aluminum has good corrosion resistance and weldability.

| Alloy | Al | Si | Cu | Mg | Zn | Mn | Fe | Others:Each |

| 1060 | 99.6 | 0.25 | 0.05 | 0.03% | 0.05 | 0.03 | 0.35 | 0.03 |

Mechanical properties of 1060 aluminum coil

The hardness standard of 1060 aluminum refers to its tensile strength and hardness values. According to international standards, the tensile strength of 1060 aluminum is generally between 60 and 95 MPa, and the hardness value is generally between 40 and 95HB. This range is determined based on the composition and heat treatment status of 1060 aluminum.

Product Videos

Characteristics of 1060 aluminum coil

1060 aluminum coil has the following characteristics:

(1) Excellent corrosion resistance: Since 1060 aluminum alloy has low manganese and copper content, it has good corrosion resistance, especially in atmospheric environments.

(2) Good welding performance: 1060 aluminum alloy has very good weldability and can be welded using various welding methods.

(3) Good cold working properties: 1060 aluminum alloy has good cold working properties and can be used for various cold workings, such as stamping, stretching, bending, etc.

(4) High toughness: 1060 aluminum alloy has high toughness and can withstand large impacts and vibrations.

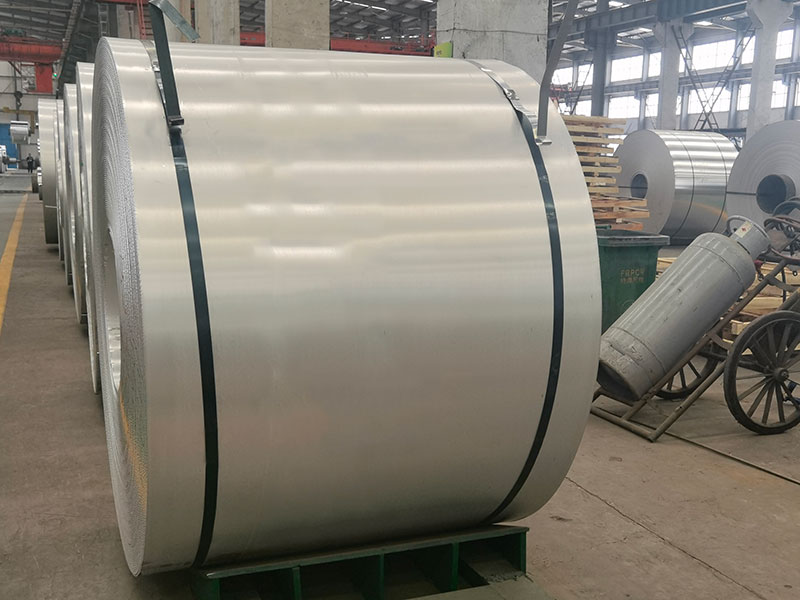

1060 Aluminum Coil DC / CC Available Size Range

| Alloy | 1060 |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, T4, T6, T651. |

| Thickness(mm) | 0.2-500 |

| Width(mm) | 100-2650 |

| Standards | GB, EN, ASTM, AISI, JIS, DIN. |

| Surface Treatment | Anodizing, Color coating, Embossing, Lamination, Polishing etc. |

| Packaging | Standard export wooden box/pallet packaging, suitable for sea transportation |

1060 Aluminum Coil DC / CC Temper designation (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

1060 Aluminum Coil DC / CC Application

1060 aluminum alloy coil is widely used in various industrial fields, such as automobile manufacturing, aerospace, electronic appliances, building decoration, etc.

For example, in automobile manufacturing, 1060 aluminum coil can be used to make automobile bodies, wheel hubs and other components; in the aerospace field, 1060 aluminum coil can be used to make aircraft engine parts, missile casings, etc.

In addition, 1060 aluminum coil is also widely used in packaging, furniture manufacturing and other fields.

To sum up, 1060 aluminum coil has the characteristics of high purity, lightness, good thermal conductivity, good electrical conductivity, and stable processing performance. It is widely used in construction, aviation, electronics, automobiles and other fields, and is a very important aluminum alloy material.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!