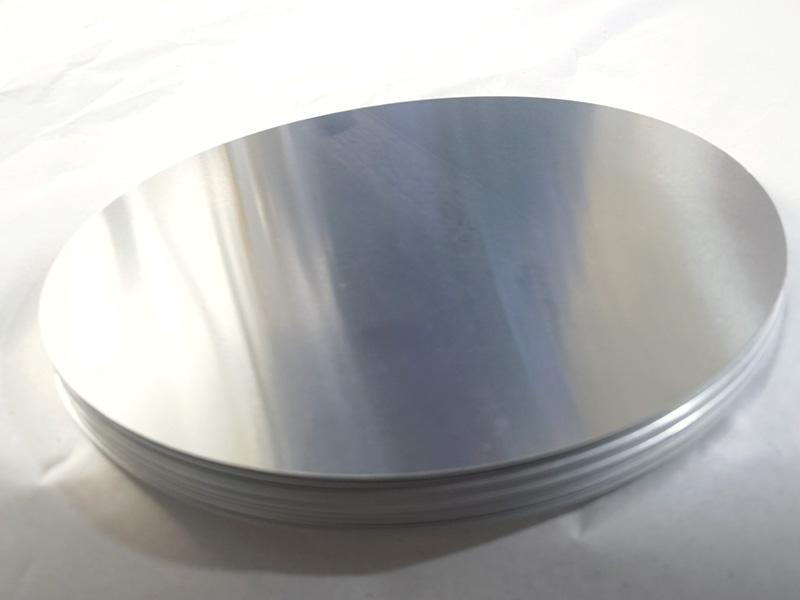

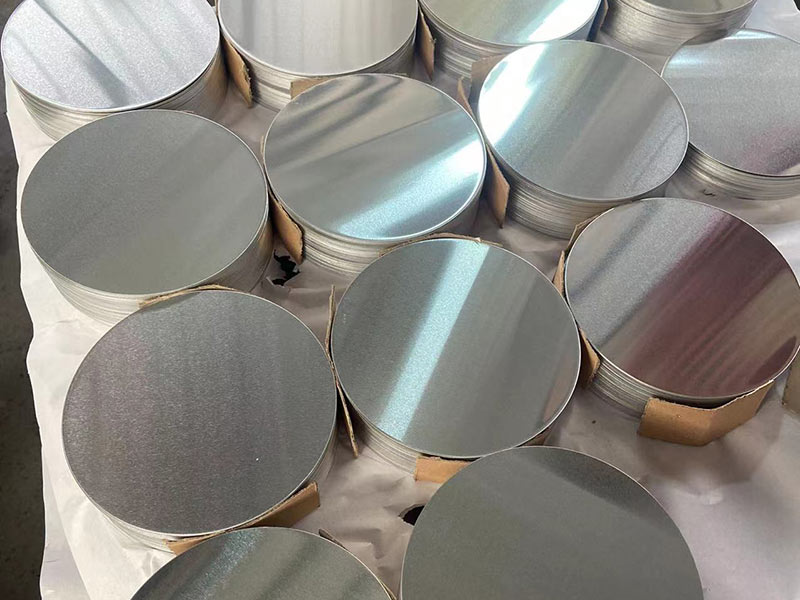

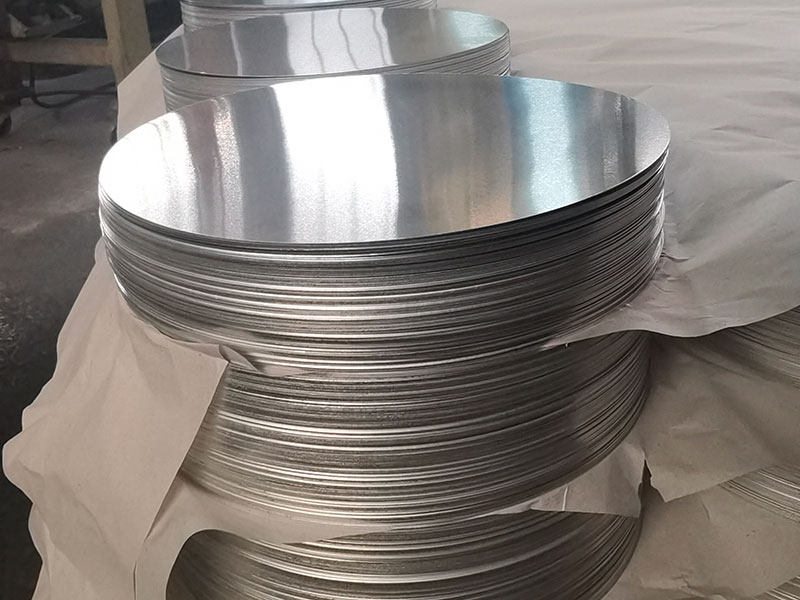

1060 Aluminum Circle and Disc

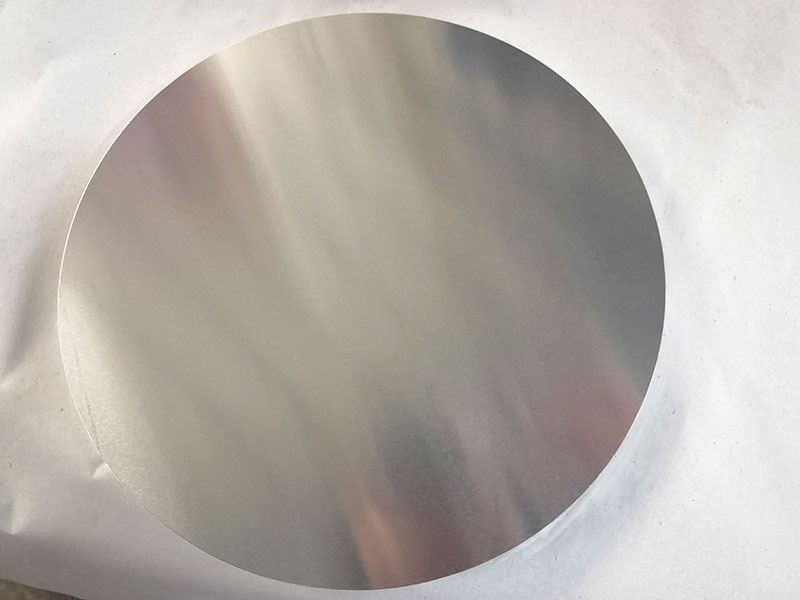

1060 aluminum circle has good elongation and tensile strength because of its high aluminum content, which can fully meet the conventional processing requirements (stamping, stretching) and has high formability.

Email: export@xienuoenterprise.com

1060 Aluminum Circle and Disc

1060 stamped aluminum discs belong to the 1000 series alloys.

The notable feature of 1060 stamped aluminum wafers is that the aluminum content can reach more than 99.60%, so 1060 stamped aluminum wafers are also often called pure aluminum.

1060 Aluminum Circle DC / CC Alloy Designation (For Reference)

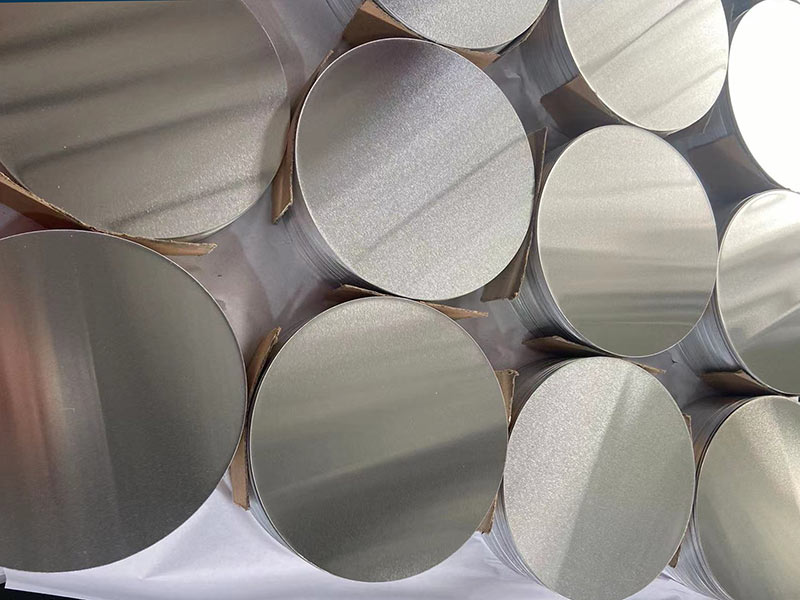

1060 aluminum discs blank of XieNuo Aluminum Company is produced according to the standards of chinese GB.

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1060 | 1060 | – |

1060 Aluminum Circle DC / CC Chemical Compositing

Chemical Composition conforms to Chinese, American and European standard specification (For Reference)

| Alloy | Al | Si | Cu | Mg | Zn | Mn | Fe | Others:Each |

| 1060 | 99.6 | 0.25 | 0.05 | 0.03% | 0.05 | 0.03 | 0.35 | 0.03 |

Product Videos

Mechanical Properties Of 1060 Aluminum Circle

| Tensile strength σb (MPa) | 110-136 |

| 1060 aluminum disc-elongation δ10 (%) | 3-5 |

| The data will be different in different states, this is the normal range value | |

1060 Aluminum Circle CC / DC Diameter Tolerance

| Nominal Diameter | Tolerance |

| Diameter tolerance | +/- 1mm |

1060 Aluminum Circle CC / DC Temper (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

Characteristics Of 1060 Aluminum Circle

1060 aluminum circle has good elongation and tensile strength because of its high aluminum content, which can fully meet the conventional processing requirements (stamping, stretching) and has high formability.

1060 aluminum disc belongs to the more common aluminum sheet alloy series in the casting-cold rolling process. The de-processing processes we can provide you include H24 state, H14 state, H16 state, H22 state, O state and non-annealed H18 state.

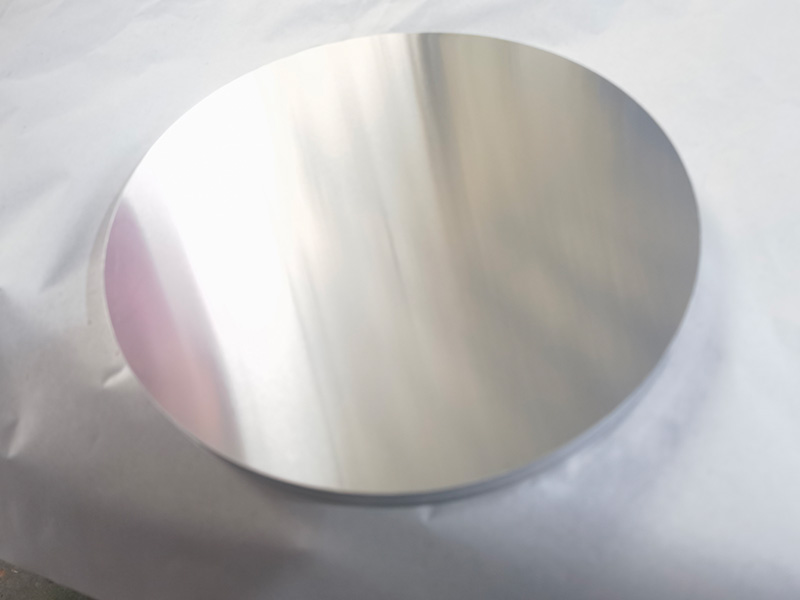

Application Of 1060 Aluminum Circle

1060 aluminum circle are widely used in products that do not require high strength.

Products are commonly used in signboards, billboards, building exterior decorations, bus bodies, high-rise building and factory wall decorations, kitchen sinks, lamp holders, fan blades, electronic parts, chemical instruments, thin plate processing parts, deep drawing or spinning concave parts. Shaped utensils, welded parts, heat exchangers, clock surfaces and disks, nameplates, kitchenware, decorations, reflective appliances, etc.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!