1050 Aluminum Sheet and Plate

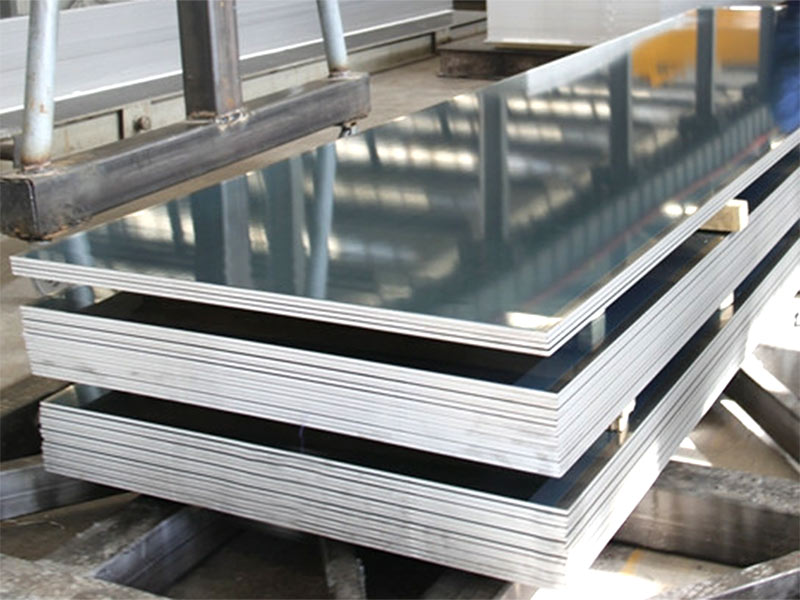

1050 aluminum sheet plate contains more than 99.5% aluminum and is one of the industrial pure aluminum. 1050 aluminum plate sheet has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, but low strength.

Email: export@xienuoenterprise.com

1050 Aluminum Sheet and Plate

What is the 1050 aluminum sheet plate?

1050 aluminum sheet plate contains more than 99.5% aluminum and is one of the industrial pure aluminum. 1050 aluminum plate sheet has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, but low strength. It cannot be strengthened by heat treatment. Strength can be increased by cold deformation.

Compared with 1060 aluminum plate sheet, the aluminum content of 1050 is slightly lower than that of 1060 (99.60%). Relatively speaking, the higher the aluminum content, the softer the material. 1060 is suitable for stretching and other products.

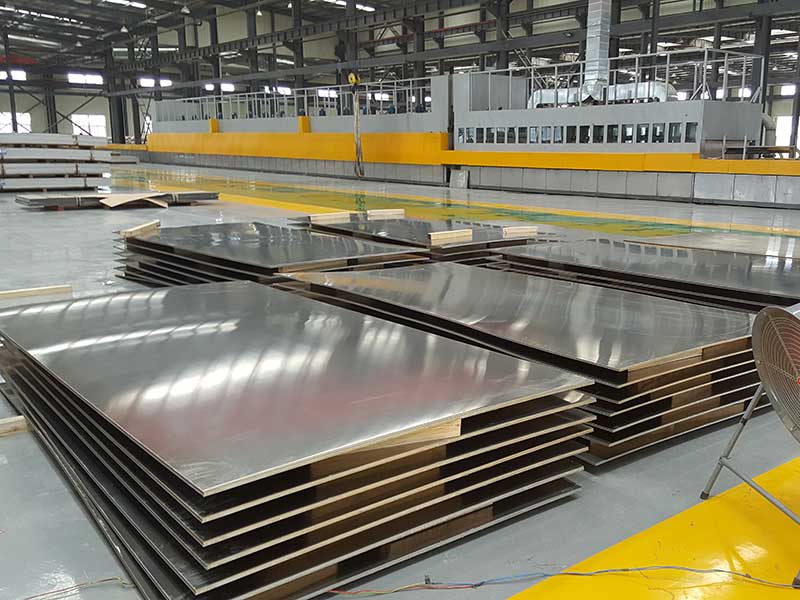

Hot selling 1050 aluminum sheet plate

Xienuo has 25 years of experience in the production of aluminum products. We have 4 semi-continuous casting production lines, 4 continuous casting and rolling production lines, and 32 other large-scale processing equipment. The monthly supply capacity of aluminum plates can reach 10,000 tons per month.

Xienuo can produce 1050 aluminum plates with widths from 20mm to 2650mm and thicknesses from 0.1 to 500mm.

| Alloy | 1050 |

| Temper | H24, H14, H12, H26, H18, O |

| Thickness | 0.1mm-500mm |

| Width | 20mm-2650mm |

| Regular width | 1000/1220/1250/1500/2000mm/2650mm |

| Length | Up to 16000 mm |

| RegularLength | 2000/2440mm/3000/6000/16000mm |

| Standard | AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

| MOQ | Generally, the trial order will be accepted |

| HS code | 76061199 |

| Lead Time | 7-35 days delivery, global export |

| Price Term | CIF CFR FOB EX-WORK or according to negotiation |

| Payment Term | TT, LC at sight or according to negotiation |

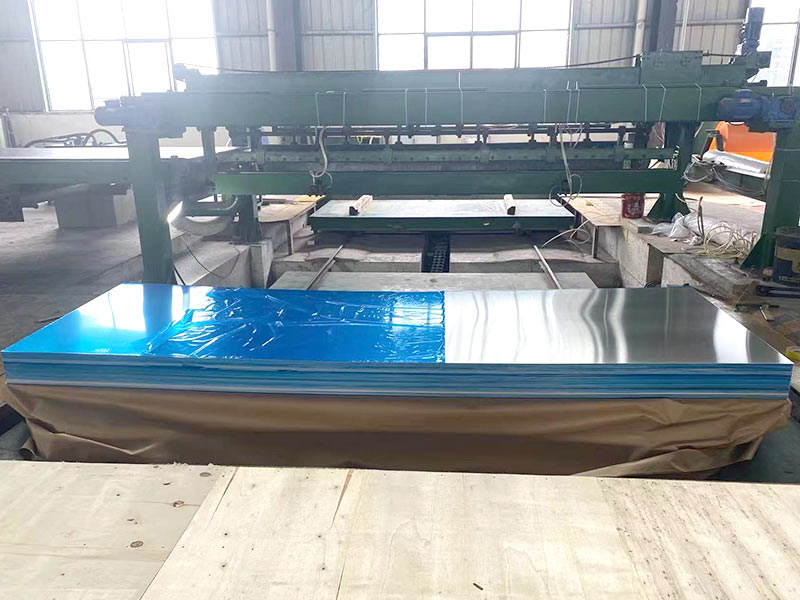

| Packaging and packing | Standard seaworthy export packaging. With protection(covering with brown paper and plastic film). |

| Supply Ability | 10, 000 tons per Month |

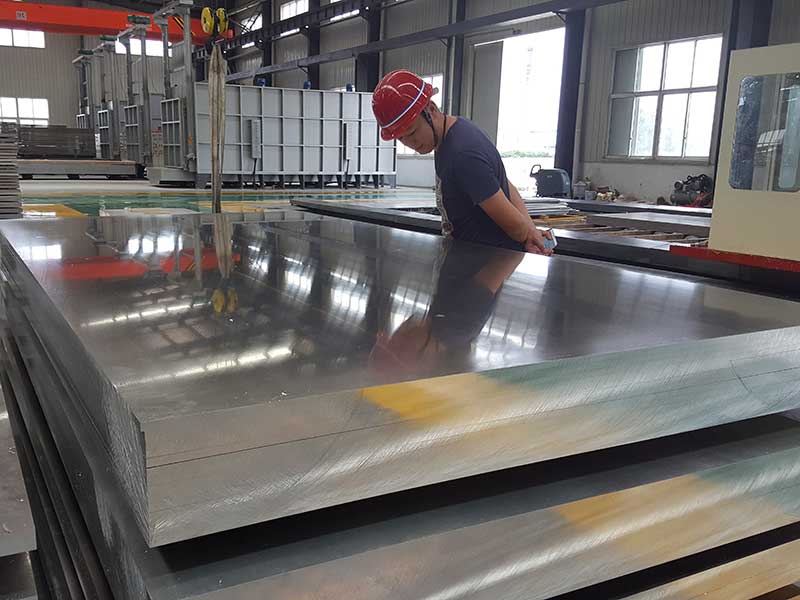

| Surface treatment | single-sided or double-sided lamination, paper addition, and other additional aluminum plate processes |

Product Videos

1050 Aluminum equivalent grades

| EN | China | Japan | India | ISO |

| EN AW-1050A/Al99.5 | 1050A(L3) | A1050 | 19500 | A99.5 |

Component Elements Properties

| Component | Content(%) |

| Iron, Fe | <= 0.4 |

| Silicon, Si | <= 0.25 |

| Copper, Cu | <= 0.05 |

| Manganese, Mn | <= 0.05 |

| Magnesium, Mg | <= 0.05 |

| Zinc, Zn | <= 0.05 |

| Titanium, Ti | <= 0.03 |

| Other, each | <= 0.05 |

| Aluminum, Al | >= 99.60 |

Physical Property

| Density | 2.71g/cm3 |

| Melting Point | 650°C |

| Thermal Expansion | 24 x10^-6 /K |

| Modulus of Elasticity | 71GPa |

| Thermal Conductivity | 222W/m.K |

| Electrical Resistivity | 0.0282 x10^-6 Ω.m |

Mechanical Property

| Tensile Strength | 105 - 145 MPa |

| Proof Stress | 85 Min MPa |

| Hardness Brinell | 34HB |

| Elongation | A - 12 Min % |

Features

1. 1050 aluminum plate has good forming and processing properties

2. Good electrical and thermal conductivity, often used as transformer belts

3. Long service life, low cost, and high recycling value

4. 1050 aluminum plate has bright color and beautiful appearance

5. Has good corrosion resistance

Application

1050 pure aluminum plate has a wide range of applications and is often used in fields that do not require high mechanical properties.

Home: 3C product panels, decorations, lighting fixtures, kitchen utensils

Construction: architectural decoration, curtain wall panels, building waterproof panels, nameplates

Transportation: billboards, traffic signs, signs

Industrial: Food and beverage packaging, cable jacketing, heat exchangers, chemical containers, heat exchangers, etc.

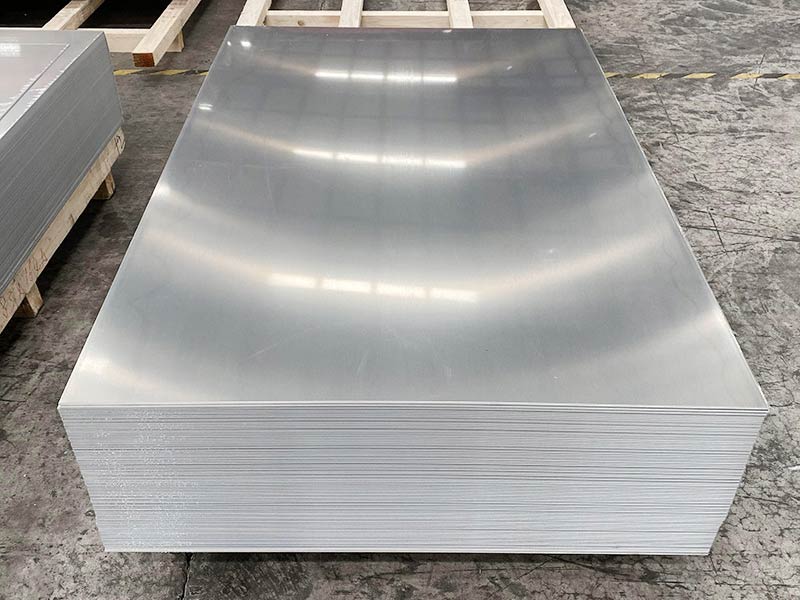

1050 aluminum alloy packaging and delivery

1. Plastic or kraft paper packaging is used to prevent moisture and rain, ensuring that the aluminum panels are clean and free of dirt during transportation (each package has a moisture-proof desiccant);

2. Install wooden pallets and reinforce them with steel strips to avoid collisions during transportation and ensure that the geometric shape of the aluminum plates remains unchanged;

3. They are all packaged in wooden boxes and pallets with fumigation markings;

4. Packaging according to other packaging requirements of customers;

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!