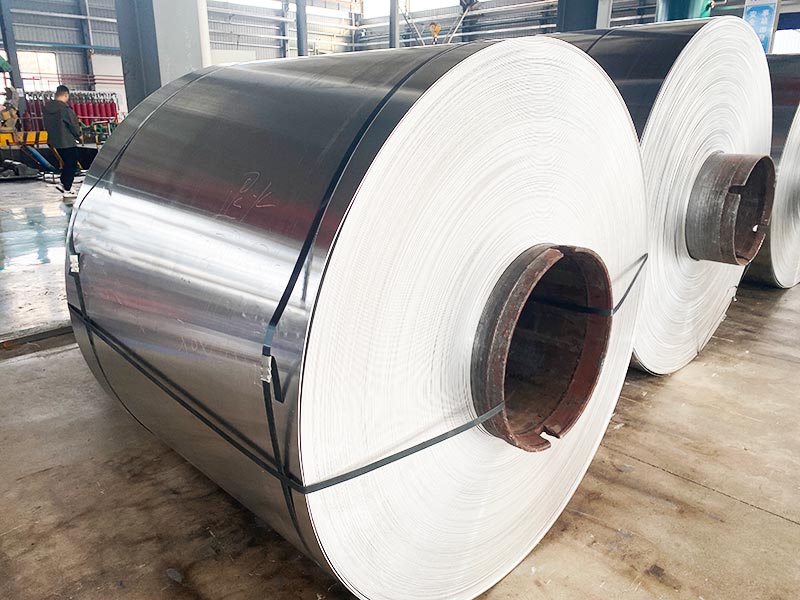

1050 Aluminum Coil and Strip

1050 aluminum coil has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, and can accept contact welding and gas welding.

Email: export@xienuoenterprise.com

1050 Aluminum Coil and Strip

1050 aluminum coil is a product in the pure aluminum series. The last two Arabic numerals of the 1050 series are 50. According to the international brand naming principles, the aluminum content must reach more than 99.5% to be a qualified product.

1050 aluminum coil has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, etc., but it has low strength and good processability.

1050 Aluminum Coil DC / CC Chemical Compositing

| Alloy | Al | Si | Cu | Mg | Zn | Mn | Ti | V | Fe |

| 1050 | 》99.5% | 《0.25% | 《0.05% | 《0.05% | 《0.05% | 《0.05% | 《0.03% | 《0.05% | 0.000~0.400 |

1050 Aluminum Coil DC / CC mechanical properties

| Tensile strength σb (MPa) | 55~130 |

| Elongation δ10 (%) | 3~15 |

| Note | Mechanical properties of pipes at room temperature |

Product Videos

1050 Aluminum Coil DC / CC Available Size Range

| Alloy | 1050 |

| Temper | O, H12, H14, H16, H18, H19, H22, H24, H26, H28, H32, H34, H36, H38, H111, H112, T4, T6, T651. |

| Thickness(mm) | 0.2-500 |

| Width(mm) | 100-2650 |

| Standards | GB, EN, ASTM, AISI, JIS, DIN. |

| Surface Treatment | Anodizing, Color coating, Embossing, Lamination, Polishing etc. |

| Packaging | Standard export wooden box/pallet packaging, suitable for sea transportation |

Characteristics of 1050 Aluminum Coil

1050 aluminum coil has the characteristics of high plasticity, corrosion resistance, good electrical and thermal conductivity, but low strength, not strengthened by heat treatment, poor machinability, and can accept contact welding and gas welding.

The production process is relatively simple and the price is relatively cheap. It is a series commonly used in conventional industries.

1050 aluminum coil heat treatment:

1) Complete annealing: heating to 390~430℃; depending on the effective thickness of the material, the holding time is 30~120min; cooling in the furnace to 300℃ at a speed of 30~50℃/h, and then air cooling.

2) Rapid annealing: Heating at 350~370℃; depending on the effective thickness of the material, the holding time is 30~120min; air or water cooling.

3) Quenching and aging: quenching at 500~510℃, air cooling; artificial aging at 95~105℃, 3h, air cooling; natural aging at room temperature for 120h

1050 Aluminum Coil DC / CC Application

1050 aluminum coil has good formability and surface treatment properties. Because it is pure aluminum, its strength is low. The higher the purity, the lower the strength. It is often used in daily necessities, lighting fixtures, reflective panels, decorations, chemical industry containers, heat sinks, signs, electronics, lamps, nameplates, electrical appliances, stamping parts and other products. In some situations where high corrosion resistance and formability are required, but strength is not required, chemical equipment is a typical use.

| Type | Application |

| Food Packaging | Beverage can end, can tap, cap stock, etc. |

| Construction | ACP sheet, Curtain walls, cladding, ceiling, heat insulation and venetian blind block, etc. |

| Transportation | Automobile parts, bus bodies, aviation and ship-building and air-cargo containers, etc. |

| Electronic Appliance | Electric fan blade, Electrical appliances, phone shell, PCB board drilling guide sheets, lighting and heat radiating materials, etc. |

| Consumer Goods | Parasols and umbrellas, cooking utensils, and sports equipment, etc. |

| Other | Oil tank, Storage Tanks, Pressure Vessels |

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!