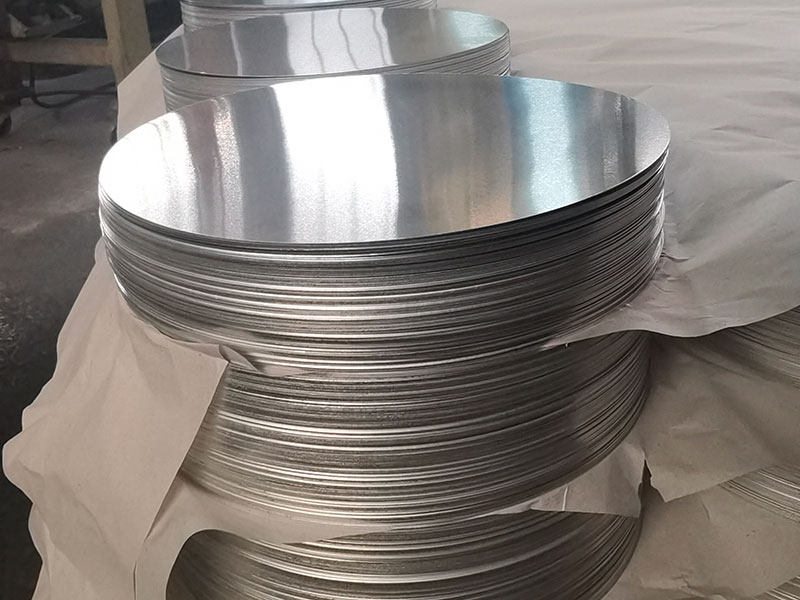

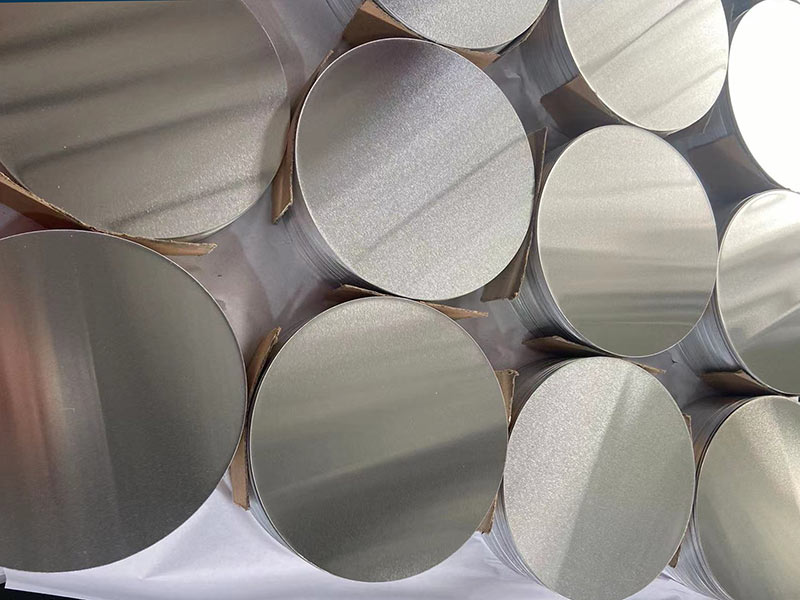

1050 Aluminum Circle and Disc

1050 aluminum alloy is formed by adding a small amount of copper element to pure aluminum. It has excellent forming and processing characteristics, high corrosion resistance, good weldability and electrical conductivity.

Email: export@xienuoenterprise.com

1050 Aluminum Circle and Disc

1050 aluminum alloy is formed by adding a small amount of copper element to pure aluminum. It has excellent forming and processing characteristics, high corrosion resistance, good weldability and electrical conductivity.

1050 Aluminum Circle DC / CC Alloy Designation (For Reference)

1050 aluminum discs blank of XieNuo Aluminum Company is produced according to the standards of chinese GB.

| Alloy Series | Chinese Standard | American Standard | European Standard |

| 1xxx Series | 1050 | 1050 | – |

1050 Aluminum Circle DC / CC Chemical Compositing

Chemical Composition conforms to Chinese, American and European standard specification (For Reference)

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others:Each | Al:Min. |

| 1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 99.5 |

Product Videos

Mechanical Properties Of 1050 Aluminum Circle

| Tensile strength σb (MPa) | 95~125 |

| Conditional yield strength σ0.2 (MPa) | ≥75 |

| Note | Mechanical properties of pipes at room temperature |

| Specimen dimensions | all wall thicknesses |

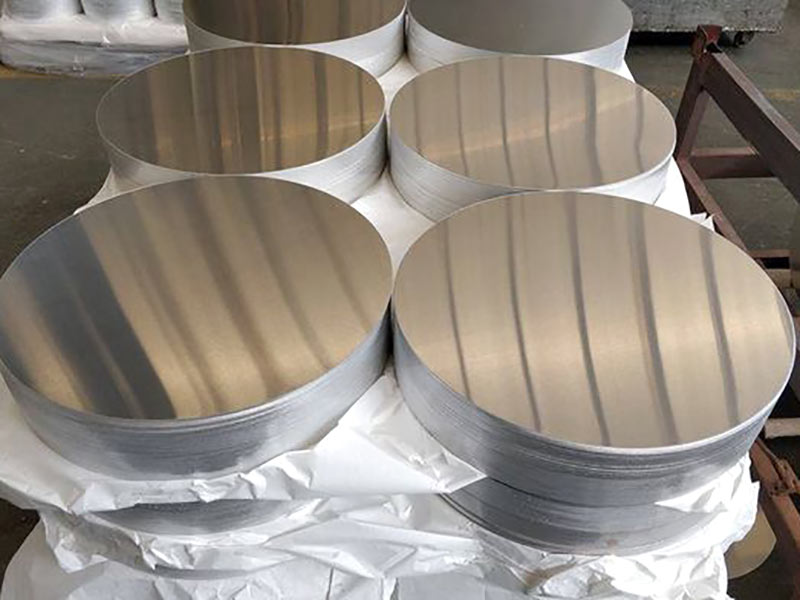

1050 Aluminum Circle CC / DC Diameter Tolerance

Due to different temperaments, the dimensions of the final product may vary slightly. But the tolerance range is very small, according to the table below.

| Nominal Diameter | Tolerance |

| Diameter tolerance | +/- 1mm |

1050 Aluminum Circle CC / DC Temper (For Reference)

| Temper | Definition |

| O | Annealed |

| H12 | Strain Hardened, 1/4 Hard |

| H14 | Strain Hardened, 1/2 Hard |

| H16 | Strain Hardened, 3/4 Hard |

| H18 | Strain Hardened, Full Hard |

| H22 | Strain Hardened and Partially Annealed, 1/4 Hard |

| H24 | Strain Hardened and Partially Annealed, 1/2 Hard |

| H26 | Strain Hardened and Partially Annealed, 3/4 Hard |

| H28 | Strain Hardened and Partially Annealed, Full Hard |

Characteristics Of 1050 Aluminum Circle

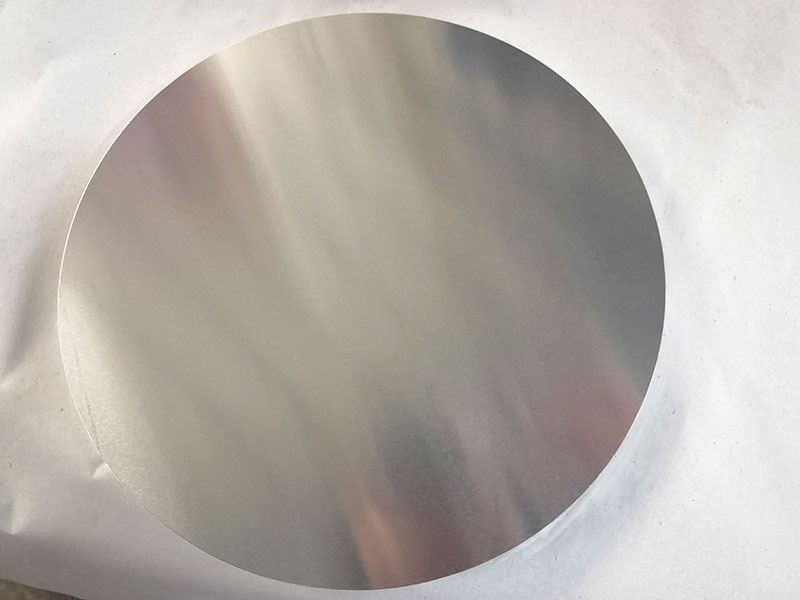

1. Hardness characteristics: Uniform hardness, suitable for complex stamping, bending, stretching, and shaping, and not easy to break.

2. Surface treatment characteristics: pure material, suitable for high requirements and stable anodizing surface treatment

Application Of 1050 Aluminum Circle

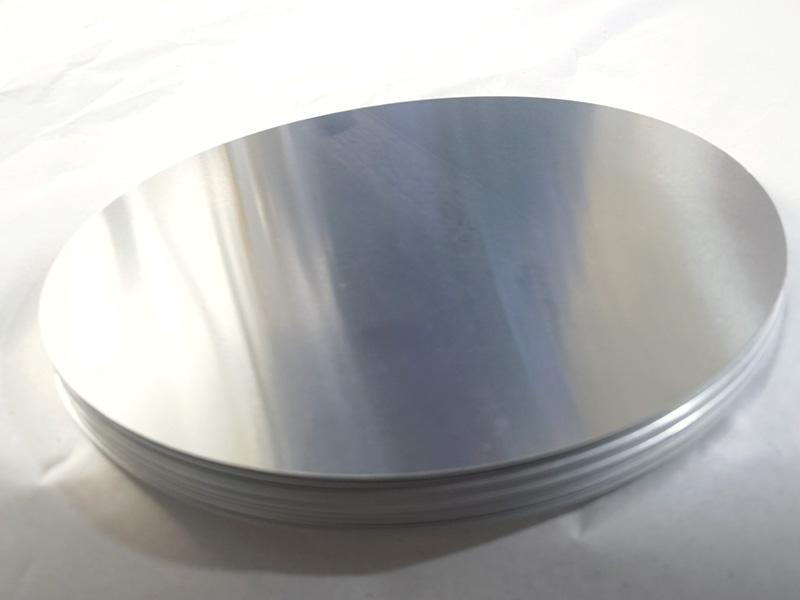

1050 aluminum disc has good cold forming characteristics, with an elongation between 35% and 38%, which is stable and of higher value.

Widely used in products that do not require high strength, such as chemical instruments, thin plate processing parts, deep drawn or spinning concave vessels, welded parts, heat exchangers, clock surfaces and disks, nameplates, kitchenware, decorations, reflective equipment, etc. .

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!